The influence of Vanadium (V) on steel properties

Vanadium (V) is a crucial alloying element in steel, known for its significant strengthening effects. It enhances steel’s mechanical properties by refining the grain structure and forming carbides or nitrides. These processes increase the strength and hardness of steel, making vanadium an essential component in high-performance steels used for structural parts, tool steels, and wear-resistant components.

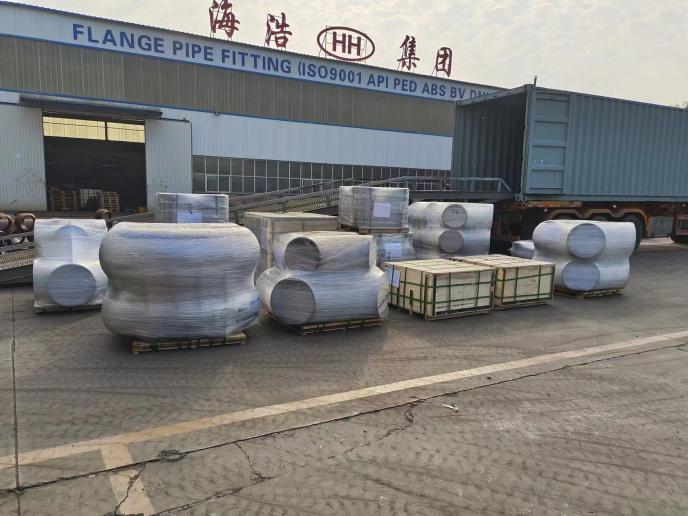

HAIHAO GROUP

Impact on Microstructure and Heat Treatment

1.Grain Refinement:

Vanadium forms a continuous solid solution with iron (Fe) and significantly narrows the austenite phase region. This grain refinement increases the toughness of the steel, particularly in low-temperature applications. Even small amounts of vanadium can effectively inhibit grain growth, which is critical for maintaining impact toughness and wear resistance.

2.Formation of Carbides and Nitrides:

Vanadium has a strong affinity for carbon (C), nitrogen (N), and oxygen (O), leading to the formation of stable carbides, nitrides, and oxides within the steel. These compounds enhance the steel’s high-temperature strength and resistance to oxidation, which is vital for applications in high-temperature environments.

3.Adjusting Hardenability:

The presence of vanadium allows for the control of steel’s hardenability by adjusting the austenitization temperature. By varying the vanadium content in austenite and the amount of undissolved carbides, the actual grain size and hardenability of the steel can be fine-tuned. While vanadium in solid solution form increases hardenability, its presence as carbides can decrease it, providing flexibility in steel processing.

4.Thermal Stability:

The stable, refractory carbides formed by vanadium maintain fine grain structures at higher temperatures, greatly reducing the steel’s susceptibility to overheating. This stability ensures that the steel retains its mechanical properties even under thermal stress.

Prefabricated Pipes

Impact on Mechanical Properties

1.Increased Toughness:

Vanadium refines the grain structure of steel, leading to improved toughness. This effect is particularly beneficial for low-temperature steels, where maintaining impact toughness is critical.

2.Carbide Precipitation and Strength:

Higher concentrations of vanadium can lead to the formation of clustered carbides, which may reduce the overall strength of the steel if precipitated within the grains. However, when dispersed appropriately, vanadium carbides significantly enhance the high-temperature creep resistance and long-term strength of steel.

3.Wear Resistance:

Vanadium carbides are among the hardest and most wear-resistant metal carbides. Their dispersion throughout the steel matrix improves the hardness and wear resistance, particularly in tool steels, extending the lifespan of the material.

4.Deoxidation and Grain Refinement:

Vanadium is an effective deoxidizer in steel production. Adding 0.5% vanadium to steel can refine the grain structure, increasing both strength and toughness. Additionally, vanadium carbides enhance resistance to hydrogen corrosion at high temperatures and pressures, making the steel more durable in harsh environments.

Vanadium is a versatile and powerful alloying element that enhances the performance of steel in multiple ways. By refining grain structures, forming stable carbides and nitrides, and adjusting hardenability, vanadium improves the strength, toughness, and wear resistance of steel. Its role in deoxidation and resistance to hydrogen corrosion further underscores its importance in high-performance applications. Despite a slight reduction in high-temperature oxidation resistance, vanadium’s overall benefits make it indispensable in the production of advanced steel grades used in demanding environments.

Related article:

The impact of hydrogen on steel performance

The role of carbon in steel performance

The influence of silicon on steel performance

The impact of Manganese on steel performance

The role of Boron in enhancing steel properties

The impact of Sulfur (S) on steel performance

The role of Potassium (K) and Sodium (Na) in steel