The role of Boron in enhancing steel properties

Boron (B) is a potent alloying element that, even in trace amounts, can significantly enhance the hardenability of steel. By increasing the hardenability, boron enables the formation of a more uniform hardened layer during quenching, thereby improving the strength and hardness of the steel. The addition of small amounts of boron allows for the reduction of other, more expensive alloying elements like nickel and chromium, achieving similar hardenability effects at a lower cost. Additionally, boron enhances the creep resistance of steel. However, excessive boron content may increase brittleness, so its concentration must be carefully controlled.

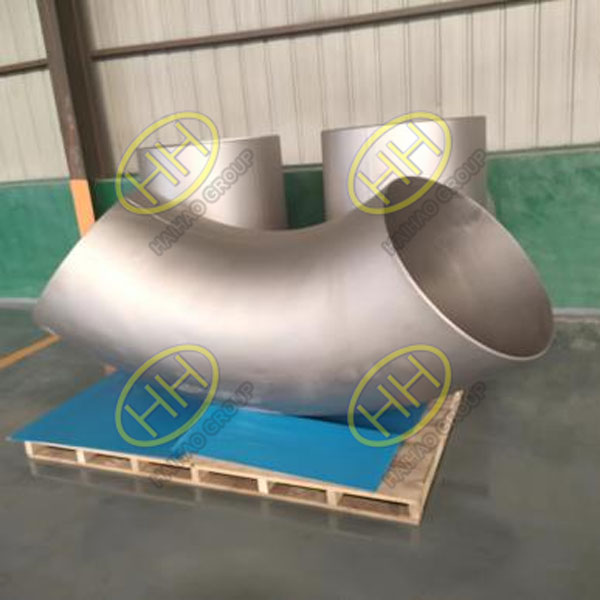

Large size pipe fittings

Effects on Microstructure and Heat Treatment

Microstructure Impact:

Boron has a profound impact on the microstructure of steel, particularly in enhancing its hardenability. During quenching, boron atoms tend to accumulate at the austenite grain boundaries, forming a protective layer that inhibits the formation of ferrite and pearlite. This suppression allows for a more effective transformation of austenite into martensite, leading to a harder and more durable steel structure.

ANSI ASME B16.11 ASTM A105 threaded 90 degree elbows

Heat Treatment Impact:

The presence of boron in low-alloy steels enables these steels to achieve high levels of hardness and strength, even with relatively low carbon content, following quenching. This makes boron-treated steels (often referred to as “boron steels”) highly desirable for manufacturing components that require superior strength and wear resistance. The enhanced mechanical properties of boron steels make them suitable for applications in industries where high performance under stress is crucial, such as in automotive parts, construction equipment, and various high-strength tools.

Boron is a highly effective alloying element in steel production, offering significant improvements in hardenability and mechanical properties. By facilitating the formation of martensite and reducing the need for more costly alloying elements, boron not only enhances the performance of steel but also contributes to cost efficiency in its production. However, the benefits of boron must be balanced against the risk of increased brittleness, making precise control of its concentration essential in steel manufacturing processes.

Related article:

The impact of hydrogen on steel performance

The role of carbon in steel performance

The influence of silicon on steel performance