An article to take you through pressure pipeline system and their characteristics

In the complex world of fluid dynamics, pressure pipes play a key role in transporting gases and liquids under controlled pressure conditions. However, not every pipeline can be called a pressure pipeline. Two key criteria define this professional category:

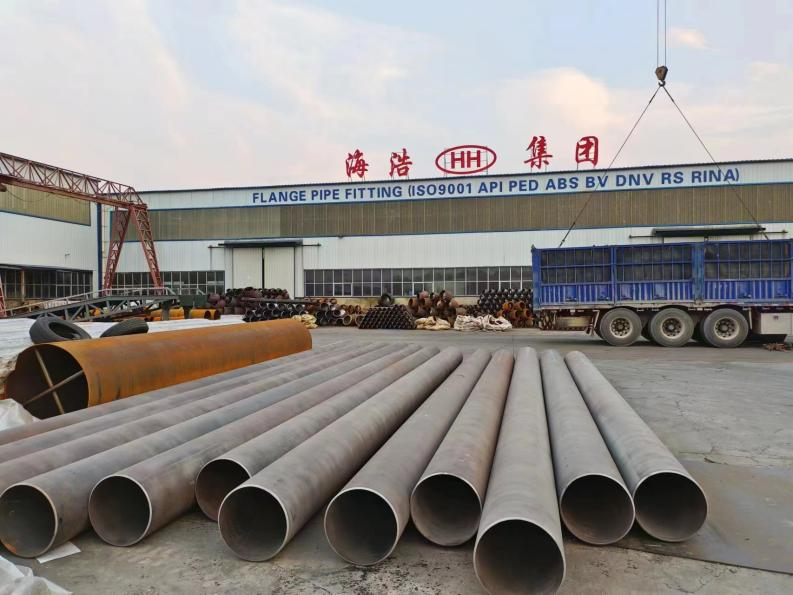

HAIHAO GROUP

Pressure >= 0.1 MPa (gauge pressure)

Pipe diameter (DN) >= 25mm

Characteristics of pressure pipelines:

1.Pressure pipelines operate as a coordinated system and any disturbance can have widespread effects.

2.Pressure pipelines have a high aspect ratio and are prone to instability, and their stress conditions are more complex than pressure vessels.

3.The fluid flow in the pipeline is complex, the buffer margin is small, and the working conditions change frequently, such as high temperature, high pressure, low temperature, low pressure, displacement and deformation, wind, snow, earthquake, etc., which may affect the stress of the pressure pipeline.

4.Pressure pipelines involve a variety of components and supports. Each material has specific requirements and specific technical requirements, making material selection complex.

5.Pressure pipelines may have more potential leak points than pressure vessels, and a valve usually has as many as five potential leak areas.

6.Pressure pipelines cover various categories, are huge in number, and have many links such as design, manufacturing, installation, inspection, and application management, which are very different from pressure vessels.

Prefabricated Pipes

Precautions for pressure piping:

The following pressure pipelines should be equipped with safety valves

- A safety valve should be installed on the outlet pipeline of volumetric pumps such as electric reciprocating pumps and gear pumps. The vent pipe of the safety valve should be connected to the pump inlet pipe, and an accident shutdown interlock device should be installed (except if the equipment itself has a safety valve);

- A safety valve should be installed at the outlet of each section of the combustible gas reciprocating compressor, and the vent pipe of the safety valve should be connected to the inlet pipe of each section of the compressor or to the inlet pipe of one section of the compressor;

- Pipelines where flammable gases and flammable liquids may expand beyond the design pressure when heated should be equipped with safety valves;

- Safety valves or other safety measures should be installed on liquefied hydrocarbon pipelines where both ends may be closed, resulting in pressure increase;

- When the equipment connected to the outlet of a blower, centrifugal compressor, centrifugal pump or steam reciprocating pump cannot withstand its maximum pressure, the outlet pipeline of the above-mentioned pump must be equipped with a safety valve.

Pipe static grounding:

Pipes transporting flammable or explosive liquids or gases, the flow of materials along the pipes, and the process of entering and exiting the container from the pipes will generate static electricity. The accumulation of a certain amount of electrostatic charge will cause electrostatic failure and electrostatic disaster.

Especially for chemical equipment with high temperature and high pressure, flammable, explosive, toxic and harmful, ensuring the safety of static electricity and preventing electrostatic failures and electrostatic disasters are the prerequisites for maintaining normal production order.

The metal parts of the non-conductive pipe section must be grounded, especially the metal joints in the middle, to prevent static electricity accumulation and electrostatic discharge.

large size pipe fittings

Correct selection of materials:

Strictly conduct non-destructive inspections of material defects, especially castings, forgings and high-pressure pipelines. Materials found to be defective shall not be put into use.

After installation, perform a hydraulic test. The test pressure should be 1.5 times the working pressure.

Correctly select the form and material of the steel pipe according to the process conditions of the pipeline, and must not be substituted or misused at will.

Conduct visual inspection and non-destructive inspection on the welds of pipelines to ensure welding quality.

As an expert in the field of piping systems, Haihao Group has a wealth of supporting products for pressure piping systems, including flanges, elbows, tees, pipes, etc. If you need these products, please feel free to contact us.