What we should know about epoxy coating?

First ,what’s the epoxy coating?

Epoxy coating is a two-component self-drying coating composed of epoxy resin, various color pigments, wear-resistant fillers, additives and solvents as one part, and the other part is a special curing agent.

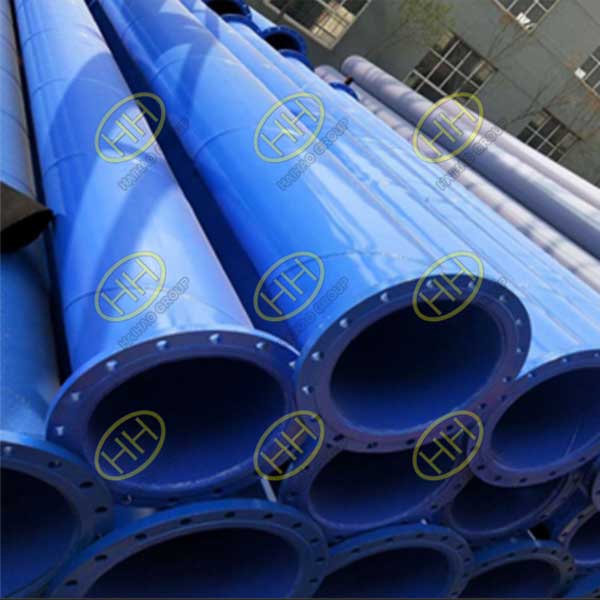

Epoxy coating steel pipe with flange

Second , what’s the Epoxy coating performance?

1.High corrosion resistance:

Epoxy coating has excellent corrosion resistance, can be resistant to oil, chemicals, weak acids and weak bases, water and moisture resistance, industrial atmosphere, isolation of salt spray, etc.;

2.Strong adhesion:

The epoxy coating coating has a strong bonding force with the substrate, and the epoxy coating film has excellent adhesion to the sandblasted steel surface, the coating does not fall off, and the adhesion is firm.

3.Excellent anti-corrosion performance:

Epoxy coating has good adhesion, excellent anti-corrosion performance and long life.

4.Excellent construction performance:

Epoxy coating can be sprayed, brushed, or rolled. The coating film has good leveling properties, and the curing reaction can also occur in low temperature environments;

5.Efficient and convenient:

The construction is simple, and the normal temperature self-curing of inorganic coatings is truly realized. When the ambient temperature is 20℃ and the relative humidity is less than 85%, the surface dry for 15 minutes and the hard dry for 2 hours can ensure high efficiency construction and achieve excellent resistance to salt spray and aging. The coating is self-repairing, and local scratches caused by external forces can still be protected. The coating is not damaged by cutting and welding. Coated welding does not affect the welding quality.

6.Excellent environmental performance:

The solid content of traditional solvent-based anticorrosive coatings can only reach 50-60%, while the solid content of high-solids heavy-duty anticorrosive coating epoxy coating can reach 70%~80%, or even 90%~100%, and the solvent is reduced by nearly half. Demonstrates good environmental performance.

Epoxy coating flanged pipe fittings

Last , what’s the application field of epoxy coating?

Epoxy coating is mainly used in harsh environments with high anti-corrosion life expectancy, prominent corrosion problems and industrial sectors that are not convenient for short-term maintenance. The application fields are as follows:

(1) Offshore engineering: offshore installations, coastal and bay structures, offshore oil drilling platforms;

(2) Transportation: highway guardrails, bridges, boats, containers, trains and railway facilities, automobiles, airport facilities;

(3) Energy industry: hydraulic equipment, water tanks, gas tanks, petroleum refining equipment, petroleum storage equipment (oil pipes, oil tanks), power transmission and transformation equipment, nuclear power, coal mines;

(4) Large industrial enterprises: papermaking equipment, medical equipment, food and chemical equipment, metal container inner and outer walls, chemical, steel, petrochemical plant pipelines, storage tanks, mining and smelting, cement plant equipment, floors with corrosive media, walls, cement member.

(5) Municipal facilities: gas pipelines and their facilities (such as gas tanks), natural gas pipelines, drinking water facilities, garbage disposal equipment, etc.

Application field of epoxy coating piping products