What is a stub end?

A stub end is a butt welded fittings that is essentially a short length of pipe.One end of a stub end is flared outwards and the other end is welded to pipe of the same nominal pipe size(NPS), material and wall thickness.

A403 WP304 SCH10S B16.9 Stub Ends

A stub end always will be used with a lap joint flange, as a backing flange.This flange connections are applied, in low-pressure and non critical applications, and is a cheap method of flanging.In a stainless steel pipe system, for example, a carbon steel flange can be applied, because they are not come in contact with the product in the pipe.

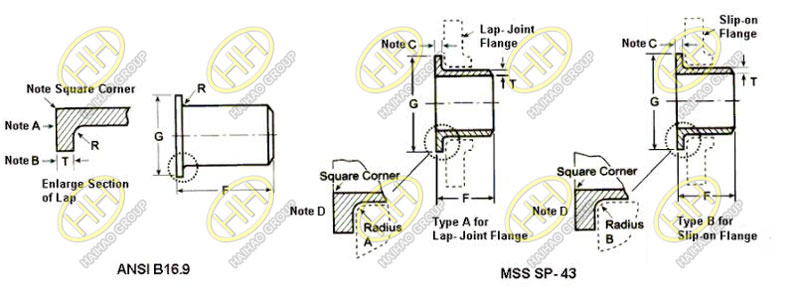

Stub ends are available in almost all pipe diameters. Dimensions and dimensional tolerances are defined in the ANSI/ASME B.16.9 standard. Light-weight corrosion resistant stub ends (fittings) are defined in MSS SP43.They are available in two standard length, long pattern(ANSI/ASME B.16.9 standard) or short pattern (MSS SP43).

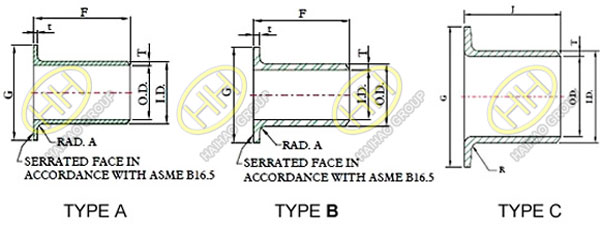

Types of stub ends

Types of stub end

There are three types of stub ends,which are Type A,Type B and Type C.Type A and B stub end are similar to forged fittings, such as elbows and tees, and type C stub end are made in customized sizes.

Stub end of Type A:

The type A stub end is manufactured and machined to fit the lap joint flange.The stub end has a matching profile and surface with the lap joint flange.The lap thickness of Type A stub end shall not be less than the minimum wall thickness of the pipe to be connected.The outer corner of Type A stub end has a radius to fit the lap joint flange,while the inner corner is squared.

Stub end of Type B:

The type B stub end is used for a standard slip on flange acting as a lap joint flange.The lap thickness of Type B stub end shall not be less than the minimum wall thickness of the pipe to be connected.The lap of type B stub end usually has a serrated face. To ensure a tight connection, chamfering on the ID side of the flange is required.

Stub end of Type C:

The type C stub ends can be used either with lap joint flanges or slip-on flanges,and which are manufactured from pipes. It is flared leaving a rounded edge at the inside diameter of the lap,and the lap thickness is 75% of the connecting pipe wall thickness.Type C stub end has a short fillet outer raduis able to accommodate any back up flange.

Demesions of stub end:

ANSI ASME B16.9 and MSS SP 43 Stub End

| Nominal Pipe Size(NPS) | Outside Dimeter at Bevel | Outside Diameter of Barrel,mm(in.) (ASME B16.9) | Length F | Radius of Fillet R,mm(in.) [Note G] | Diameter of Lap G,mm(in.)[Note H] | ||||

| MSS SP-43 | Max. | Min. | Long Pattern,mm(in.)(ASME B16.9)[Note E,F] | Short Pattern,mm(in.)(ASME B16.9)[Note E,F] | MSS | ASME&MSS Type A | MSS Type B(max.) | ||

| 1/2 | 0.84 | 22.8 (0.986) | 20.5 (0.809) | 76 (3.00) | 51 (2.00) | 2.00 | 3 (0.12) | 0.03 | 35 (1.38) |

| 3/4 | 1.05 | 28.1 (1.106) | 25.9 (1.019) | 76 (3.00) | 51 (2.00) | 2.00 | 3 (0.12) | 0.03 | 43 (1.69) |

| 1 | 1.32 | 35.0 (1.376) | 32.6 (1.284) | 102 (4.00) | 51 (2.00) | 2.00 | 3 (0.12) | 0.03 | 51 (2.00) |

| 1 1/4 | 1.66 | 43.6 (1.716) | 41.4 (1.629) | 102 (4.00) | 51 (2.00) | 2.00 | 5 (0.19) | 0.03 | 64 (2.50) |

| 1 1/2 | 1.90 | 49.9 (1.965) | 47.5 (1.869) | 102 (4.00) | 51 (2.00) | 2.00 | 6 (0.25) | 0.03 | 73 (2.88) |

| 2 | 2.38 | 62.4 (2.456) | 59.5 (2.344) | 152 (6.00) | 64 (2.50) | 2.50 | 8 (0.31) | 0.03 | 92 (3.62) |

| 2 1/2 | 2.88 | 75.3 (2.966) | 72.2 (2.844) | 152 (6.00) | 64 (2.50) | 2.50 | 8 (0.31) | 0.03 | 105 (4.12) |

| 3 | 3.50 | 91.3 (3.596) | 88.1 (3.469) | 152 (6.00) | 64 (2.50) | 2.50 | 10 (0.38) | 0.03 | 127 (5.00) |

| 3 1/2 | 4.00 | 104.0 (4.096) | 100.8 (3.969) | 152 (6.00) | 76 (3.00) | 3.00 | 10 (0.38) | 0.03 | 140 (5.50) |

| 4 | 4.50 | 116.7 (4.593) | 113.5 (4.469) | 152 (6.00) | 76 (3.00) | 3.00 | 11 (0.44) | 0.03 | 157 (6.19) |

| 5 | 5.56 | 144.3 (5.683) | 140.5 (5.532) | 203 (8.00) | 76 (3.00) | 3.00 | 11 (0.44) | 0.06 | 186 (7.31) |

| 6 | 6.62 | 171.3 (6.743) | 167.5 (6.594) | 203 (8.00) | 89 (3.50) | 3.50 | 13 (0.50) | 0.06 | 216 (8.50) |

| 8 | 8.62 | 222.1 (8.743) | 218.3 (8.594) | 203 (8.00) | 102 (4.00) | 4.00 | 13 (0.50) | 0.06 | 270 (10.62) |

| 10 | 10.75 | 277.2 (10.913) | 272.3 (10.719) | 254 (10.00) | 127 (5.00) | 5.00 | 13 (0.50) | 0.06 | 324 (12.75) |

| 12 | 12.75 | 328.0 (12.913) | 323.1 (12.719) | 254 (10.00) | 152 (6.00) | 6.00 | 13 (0.50) | 0.06 | 381 (15.00) |

| 14 | 14.00 | 359.9 (14.170) | 354.8 (13.969) | 305 (12.00) | 152 (6.00) | 6.00 | 13 (0.50) | 0.06 | 413 (16.25) |

| 16 | 16.00 | 411.0 (16.180) | 405.6 (15.969) | 305 (12.00) | 152 (6.00) | 6.00 | 13 (0.50) | 0.06 | 470 (18.50) |

| 18 | 18.00 | 462.0 (18.190) | 456.0 (17.969) | 305 (12.00) | 152 (6.00) | 6.00 | 13 (0.50) | 0.06 | 533 (21.00) |

| 20 | 20.00 | 514.0 (20.240) | 507.0 (19.969) | 305 (12.00) | 152 (6.00) | 6.00 | 13 (0.50) | 0.06 | 584 (23.00) |

| 22 | 565.0 (22.240) | 558.0 (21.969) | 305 (12.00) | 152 (6.00) | 13 (0.50) | 641 (25.25) | |||

| 24 | 24.00 | 616.0 (24.240) | 609.0 (23.969) | 305 (12.00) | 152 (6.00) | 6.00 | 13 (0.50) | 0.06 | 692 (27.25) |

- Note A: Gasket face finish shall be in accordance with ASME B16.5 for raised-face flanges.

- Note B: The lap thickness, T, shall not be less than nominal pipe wall thickness.

- Note C: Minimum lap thickness shall not be less than nominal wall thickness

- Note D: Contact faces of stub ends shall have a modified spiral or connectric serration

- Note E: When short pattern stub ends are used with larger flanges in Classes 300 and 600,with more sizes in Classes 900 and higher,and when long pattern stub ends are used with larger flanges in Classes 1500 and 2500,it may be necessary to increase the length of the stub ends in order to avoid covering the weld with the flange. Such increases in length shall be a matter of agreement between the manufacturer and purchaser.

- Note F: When special facings such as tongue and groove or male and female are employed,additional lap thickness must be provided and such additional thickness shall be in addition to (not included in) the basic lenth F.

- Note G: These dimensions conform to radius established for lap joint flanges in ASME B16.5

- Note H: This dimension conforms to standard machined facings shown in ASME B16.5. The back face of the lap shall be machined to conform to the surface on which it sits.Where ring joint facing are to be applied,use dimension K as given in ASME B16.5.

As a profisional piping manufacture,we can supply stub ends of different materials such as carbon steel,stainless steel and alloy steel.We sincerely welcome customers domestic and abroad to visit us for cooperation and development.Haihao pipe fitting factory would produce and supply the high quality pipe fitting products as per clients’ requirement.

PREV: Hex Bolt