Selecting the perfect material for your elbow

Choosing the right material for your elbow is a critical decision that directly impacts the performance and longevity of your pipeline system. With a wide range of materials available, each offering unique characteristics, it’s essential to understand the factors that influence the selection process. In this guide, we will explore the key considerations to help you make an informed decision when choosing the material for your elbow.

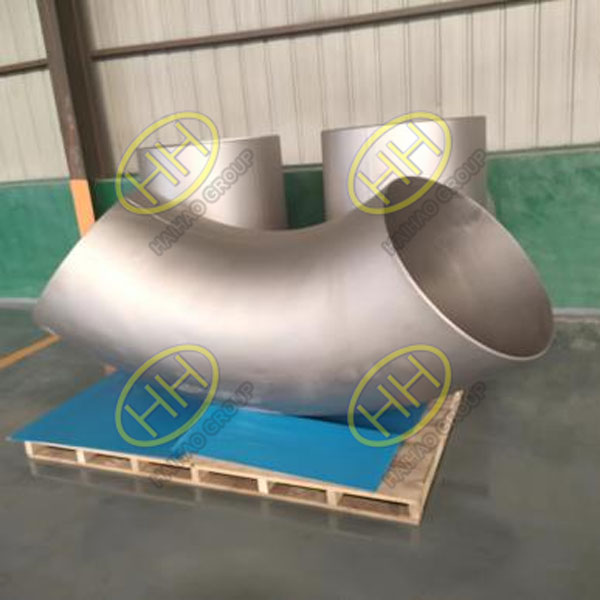

ASME B16.11 A105 Socket Weld 90 Degree Elbows

Corrosion Resistance:

One of the primary factors to consider is the corrosion resistance of the material. Different environments and fluids require specific corrosion-resistant properties. Stainless steel, such as AISI 316 or 304, is widely preferred for its excellent resistance to corrosive substances found in industries like chemical processing, offshore, and marine applications. Carbon steel with proper coatings is suitable for general applications, while alloys like Inconel and Hastelloy provide exceptional resistance in highly corrosive environments.

Temperature and Pressure:

The operating temperature and pressure of your pipeline system are crucial considerations. For high-temperature applications, materials like carbon steel, alloy steel, and stainless steel with suitable heat resistance properties are preferred. High-pressure systems may require materials with enhanced tensile strength and pressure ratings, such as duplex stainless steel or super alloys.

Fluid Compatibility:

Understanding the nature of the fluid being transported is vital in material selection. Certain fluids, such as acids, alkalis, or hydrocarbons, can be highly aggressive and require materials with specific resistance properties. It’s important to consult material compatibility charts and consider materials like PVC, CPVC, or corrosion-resistant alloys, depending on the fluid’s chemical composition.

Elbows coated FBE

Mechanical Properties:

Consider the mechanical properties required for your specific application. Factors such as tensile strength, impact resistance, and fatigue strength are crucial for ensuring the elbow can withstand the operational conditions. Carbon steel elbows offer good mechanical properties, while alloy steels provide higher strength levels for demanding applications.

Cost Considerations:

Cost is a practical consideration that should not be overlooked. Different materials come with varying price points, and it’s essential to balance the desired properties with budget constraints. While stainless steel and exotic alloys may have higher initial costs, their superior corrosion resistance and longer service life can lead to cost savings in the long run.

Choosing the right material for your elbow is a critical step in ensuring the optimal performance and durability of your pipeline system. Consider factors such as corrosion resistance, temperature and pressure requirements, fluid compatibility, mechanical properties, and cost when making your decision. Collaborating with experienced manufacturers and suppliers, such as Haihao Group, can provide valuable guidance and access to a wide range of materials, ensuring you find the perfect solution for your elbow needs. Invest in the right material today and enjoy a reliable, efficient, and long-lasting pipeline system.