Enhancing steel pipe durability exploring coatings and temperature resistance

Steel pipes serve as crucial components in various industries, from infrastructure to energy, and their longevity is of paramount importance. To ensure their durability, protective coatings are applied to steel pipes, offering resistance to corrosion, wear, and other environmental factors. Moreover, understanding the temperature resistance of these coatings is essential to maintain the pipes’ structural integrity and performance.

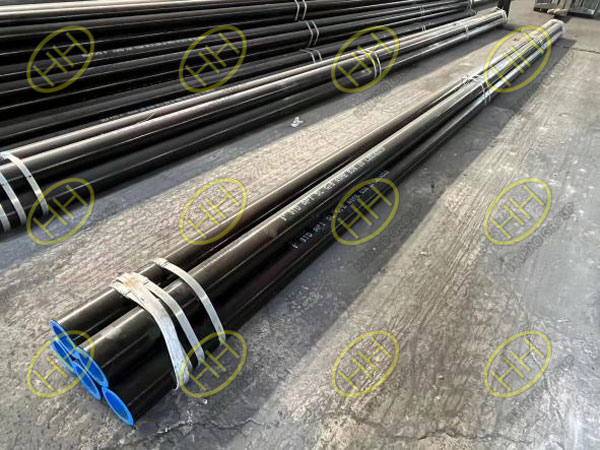

Black zinc rich epoxy paint coating steel pipe

Types of coatings and their temperature resistance:

Anti-Corrosion Paint: Widely used, epoxy or polyurethane coatings are effective against corrosion. These coatings exhibit excellent performance at temperatures up to approximately 60°C (140°F). Special high-temperature epoxy coatings can extend this range to around 150°C (302°F).

Galvanized Coatings: Galvanized coatings, while efficient against corrosion, have a lower temperature resistance. They generally remain effective up to 200°C (392°F) before becoming compromised due to zinc’s characteristics.

Sprayed Coatings: Depending on the type of paint used, sprayed coatings can offer resistance up to 60°C (140°F) to 80°C (176°F) for conventional coatings. Specialty high-temperature coatings can handle temperatures of 150°C (302°F) and beyond.

Hot-Dip Galvanization: Hot-dip galvanized coatings can withstand temperatures up to 200°C (392°F) before their protective properties are reduced.

Powder Coatings: The temperature resistance of powder coatings usually ranges from 150°C (302°F) to 200°C (392°F), based on the type of powder used.

Polyethylene (PE) Coatings: PE coatings are reliable at room temperature and below, generally effective up to 60°C (140°F).

Polyurethane (PU) Coatings: PU coatings, known for their resistance to wear and chemicals, tend to remain efficient at temperatures under 80°C (176°F).

Steel pipes coating with intergard 475HS epoxy

Choosing the right coating for the right environment:

Selecting the appropriate coating involves considering the specific application and environmental conditions the steel pipes will face. Factors such as coating thickness, exposure duration, and working temperature should all be taken into account.

At Haihao Group, we understand the critical role that coatings play in prolonging the lifespan of steel pipes. As a reputable provider of pipe solutions, we offer a range of coated pipes with various types of protective coatings. Our products are designed to excel in different environments, ensuring reliable performance and longevity.If you need to choose suitable piping products for your project, please feel free to contact us, we will provide you with suitable coating and piping products according to your needs.