Let’s learn about FBE coating

FBE coating (fusion bonded epoxy, fusion bonded epoxy powder coating) is a one-part, thermosetting powder coating that provides pipeline from optimum corrosion protection in all environments – petrochemicals, gases, corrosive substances, saltwater, freshwater, wastewater, and more .

FBE Coating Pipeline Products

1 .What‘s the advantages of FBE coating?

- Excellent adhesion to the substrate, providing long lasting corrosion protection

- Chemical and water resistance mean FBE coating can be used in a variety of environments – including soil and sour crude

- Abrasion and impact resistance protects the film from handling and stress damage

It does not shield cathodic protection, allowing protection to continue even in the case of a coating failure.

Steel pipes with FBE coating

2.How to paint the FBE ?

FBE coating is a type of powder coating, and so heat is required to cause the dry powder to melt and flow over the substrate. The main steps of the FBE coating process are outlined below.

- Surface preparation – To ensure the right surface profile for the coating, the substrate needs to be entirely free from oil and grease.we normally do sandblast.

- Coating preparation – The powder coating process requires heat in order to form a smooth and seamless film. In FBE coating this heat is provided by the part being coated – we will do preheat to the desired temperature before the coating is applied.

- Coating application and curing – Powder is applied through the fluidised bed method or through a spray gun application. The dry powder hits the heated part and melts and flows, coating the part and curing through a process of cross-linking.FBE coating uses, standards and specifications

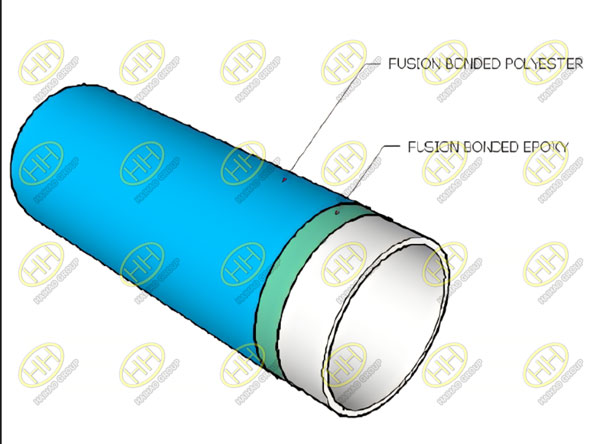

FBE Coating Darwing

3.Normally ,where do the FBE coating pipe and fittings use on?

FBE coating is specified in a range of industries and applications, especially in the oil, gas, and water pipeline industries. It is used on gas transmission pipelines, for the internal lining of desalination plants, to protect tanks, and more. Worldwide there are tens of thousands of kilometres of pipelines use FBE coating, as do uncounted valves, pumps, water fittings, cooling pipework, and tubing systems.

FBE Coating Pipeline Project

4.Now come to the point! Where to find specialists pipeline manufacture with FBE coating in China?

HEBEI HAIHAO GROUP STEEL PIPE ENGINEERING CO.,LTD is a factory who have been produce pipe ,flange and pipe fittings for 40 years , we have good business relationship with the top producers and manufacturers of fusion bonded epoxy coating in the world are AkzoNobel, Jotun, Valspar, BASF, Axalta, 3M, and Sherwin-Williams. We are capable of handling 2-inch to 60-inch diameter pipes up to 80 feet in length

If you have such requirement ,welcome to contact me : sales@haihaogroup.com