What is the difference between forged pipe fittings and cast pipe fittings?

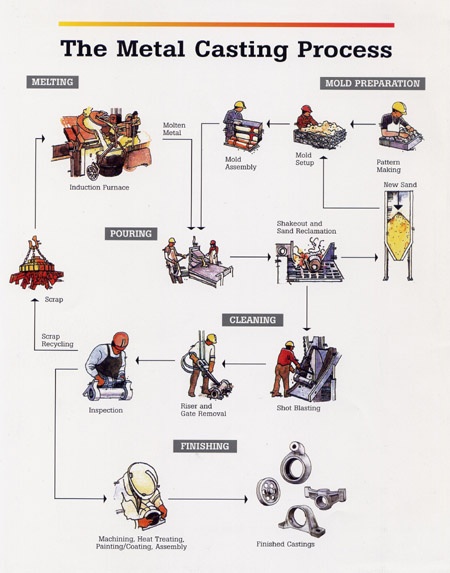

Casting pipe fittings process-Haihao Group

Casting is a metal smelting meet certain requirements in liquid and poured into the mold, after cooling and solidification, clearing process to get there casting (part or blank) of the process of a predetermined shape, size and performance.

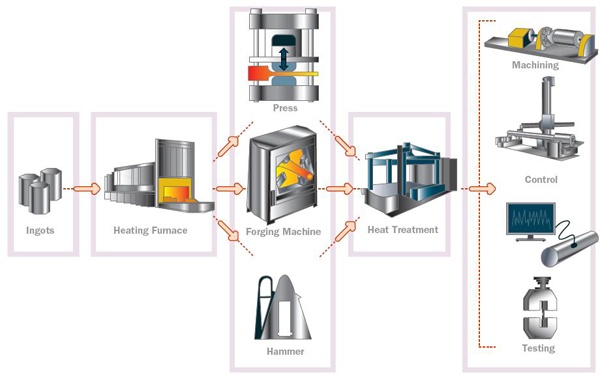

Forging is the use of a mechanical pressure on the metal blank to produce plastic deformation to obtain a certain mechanical properties, shape and size of the forging certain processing methods.

Forging pipe fittings process-Haihao Group

Forged Pipe Fittings and Cast Pipe Fittings are the following differences:

1.The cast pipe fittings mechanical properties are lower than the forged pipe fittings,which are in the same material.

2.The forged pipe fittings can ensure the continuity of the metal fibrous tissue,make the metal fibrous tissue and forged pipe fittings’ shape consistent,metal streamline complete.So it makes the parts for good mechanical properties and long service life.The forged pipe fittings used precision die forging,cold extrusion,warm extrusion process and so on,which are the cast pipe fittings cannot compared.

3.Forged pipe fittings are made using the method of forging.Forging is to use impact, forging pieces.The metal after forging can improve its organizational structure and mechanical properties,and improved the plasticity and mechanical properties of the metal.

4.Cast pipe fittings are made using the method of casting.Casting have a mold or model,fill pour molten steel,casting pieces.

Haihao group have a nearly 30 years socket weld pipe fittings manufacture experience. we can supply suitable products as per your request. Besides these standard products, we also can supply customized butt welding pipe fittings accordingly.

We sincerely welcome customers domestic and abroad to visit us for cooperation and development.