The third type test- flattening test

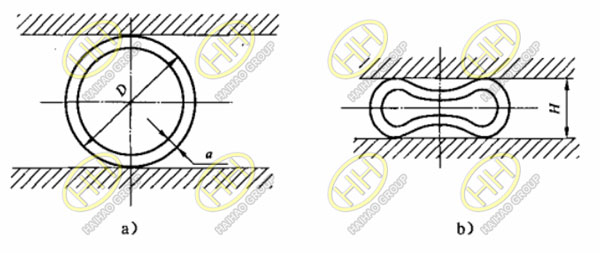

Flattening Test– The flattening test as commonly made on specimens cut from tubular products is conducted by subjecting rings from the tube or pipe to a prescribed degree of flattening between parallel plates (As shown).

Flattening test drawing

The severity of the flattening test is measured by the distance between parallel plates and varies according to tube or tube size. Flattened specimens shall not be less than 21/2 inch (63.5 mm) in length and shall be flattened and cooled to the extent required by the applicable material specifications.

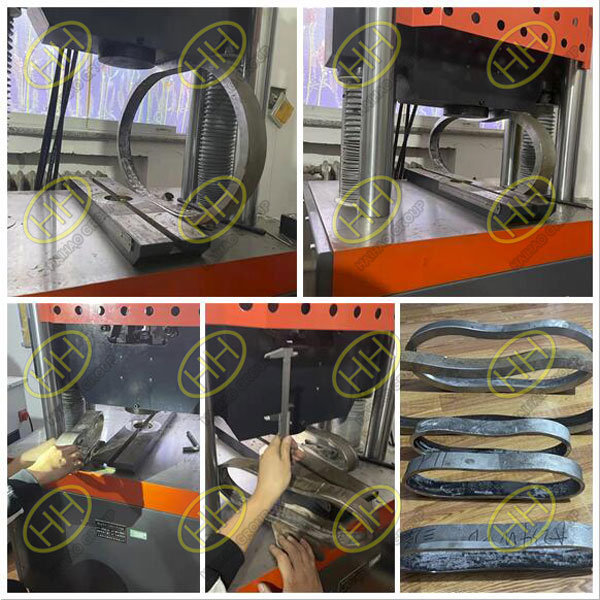

According to the requirements of DNV testing, we prepared multiple test blocks of various materials. The materials are A234 WPB,A355 P91,A420 WPL6,A403 WP304 and so on. Our flattening test was carried out at room temperature. The tester places the specimen between two pressure plates and flattens the plate perpendicular to the longitudinal axis of the pipe. Description of flattening test results shall be in accordance with the requirements of relevant product standards. When not specified in the product standard, without the use of a magnifying glass, if there is no visible crack, should be assessed as qualified. Minor cracking only at the edges and corners of the sample should not be judged as a failure.

As shown in the photo, all the test blocks passed the flattening test successfully.

Flattening Test