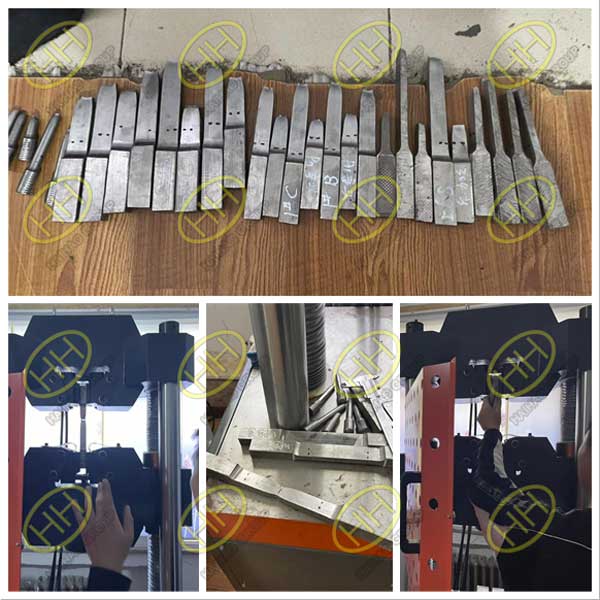

The fourth type test-tensile test

Tensile test, generally refers to the tensile test, tensile test can determine a series of material strength indicators and plastic indicators. Strength usually refers to the ability of a material to resist elastic deformation, plastic deformation and fracture under the action of external forces. Plasticity refers to the ability of metal materials to produce plastic deformation without damage under the action of load. The commonly used plasticity index is elongation and section shrinkage.

Tensile test

Specimens cut either longitudinally or transversely shall be acceptable for the tension test.At least one tension test shall be made on each heat of material and in the same condition of heat treatment as the finished fittings it represents provided that the wall thickness of the fitting and the representative sample thickness do not vary more than 1⁄4 in. (6 mm). At least one tension test per heat of weld metal shall be made after heat treatment in the same manner as the base metal.

In order to apply for DNV certificate, 12 test specimens of different materials are prepared in advance for tensile test.When the test block under the tensile action of the testing machine, slowly elongated until the moment of being pulled off, a perfect arc is drawn on the computer screen, showing the tensile strength and yield strength of the material in front of our eyes. At the same time, we use measuring equipment to measure the deformation of the sample in the test process, so as to obtain the elongation.