The influence of Zirconium (Zr) on steel performance

Zirconium (Zr) is a relatively rare element in steel production, but its addition can significantly enhance the properties of steel in specific applications. Zirconium primarily acts as a grain refiner in steel, where it forms stable carbides, nitrides, or oxides that inhibit grain growth, thereby improving the strength and toughness of the steel. Furthermore, zirconium enhances the corrosion resistance of steel, particularly in high-temperature and corrosive environments. Its addition also improves the weldability and high-temperature oxidation resistance of steel, making it valuable in aerospace, nuclear, and high-temperature applications.

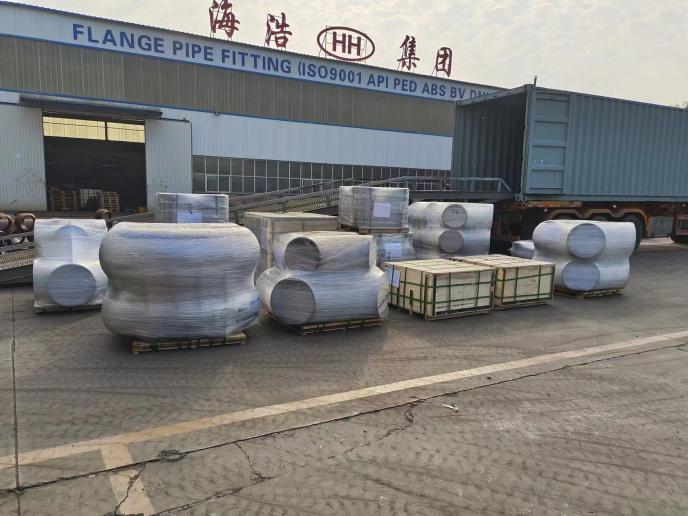

HAIHAO GROUP

Effects on Microstructure and Heat Treatment

1.High-Melting Rare Metal: Zirconium is a high-melting rare metal and a carbide-forming element. During steelmaking, it serves as a powerful deoxidizing and denitrifying agent and also plays a role in dehydrogenation and desulfurization.

2.Grain Refinement: Zirconium refines the austenite grains in steel, leading to a finer microstructure.

3.Hardenability: Zirconium, when dissolved in austenite, increases the hardenability of steel. However, if present primarily as ZrC, it can reduce the steel’s hardenability.

Effects on Mechanical Properties

1.Strain Aging and Temper Brittleness: Zirconium reduces the tendency for strain aging and temper brittleness in steel.

2.Low-Temperature Toughness: Zirconium is more effective than vanadium in improving the low-temperature brittleness of low-alloy steels.

3.Blue Brittleness: Zirconium helps mitigate the blue brittleness tendency in steel.

Effects on Physical, Chemical, and Processing Properties

1.Intergranular Corrosion Resistance: Adding small amounts of zirconium to low-carbon nickel-chromium stainless steel can prevent intergranular corrosion.

2.Hot Brittleness Resistance: Zirconium forms sulfides with sulfur, effectively preventing hot brittleness in steel. It also significantly reduces the cracking tendency in copper-containing steel.

3.Tool Steel Performance: Zirconium greatly enhances the cutting life of high-carbon tool steel and high-speed steel.

4.Weldability: Zirconium improves the weldability of steel.

Forged flanges

Applications of Zirconium in Steel

1.Specialty Steels and Alloys: Due to its scarcity, high cost, and limited solubility in steel, zirconium is primarily used in specialty steels and alloys for specific purposes.

2.Nuclear and Corrosion-Resistant Materials: Zirconium has significant applications in nuclear reactor materials and specialized corrosion-resistant equipment. Zirconium-based materials can form bulk amorphous materials with unique properties.

Although zirconium is not commonly used in standard steel grades due to its rarity and cost, its ability to enhance critical properties such as grain refinement, corrosion resistance, and mechanical performance in extreme environments makes it a valuable addition to steels intended for specialized applications.

Related article:

The impact of hydrogen on steel performance

The role of carbon in steel performance

The influence of silicon on steel performance

The impact of Manganese on steel performance

The role of Boron in enhancing steel properties

The impact of Sulfur (S) on steel performance

The role of Potassium (K) and Sodium (Na) in steel