Solution to corrosion challenges of duplex 2205 stainless steel

Introducing duplex 2205, a nitrogen-enhanced duplex stainless steel designed to address common corrosion issues faced by the 300 series stainless steels.

“Duplex” describes a range of stainless steels that are neither fully austenitic like 304 stainless steel nor purely ferritic like 430 stainless steel. The structure of duplex 2205 consists of austenite pools surrounded by a continuous ferrite phase. In the annealed condition, duplex 2205 contains approximately 40-50% ferrite. It is one of the widely used grades in the duplex stainless steel series.

The advantage of the duplex structure lies in combining the excellent qualities of ferritic alloys (stress corrosion cracking resistance and high strength) with the excellent qualities of austenitic alloys (ease of fabrication and corrosion resistance).

The use of duplex 2205 should be limited to temperatures below 600°F, as prolonged exposure to high temperatures can cause embrittlement of the steel.

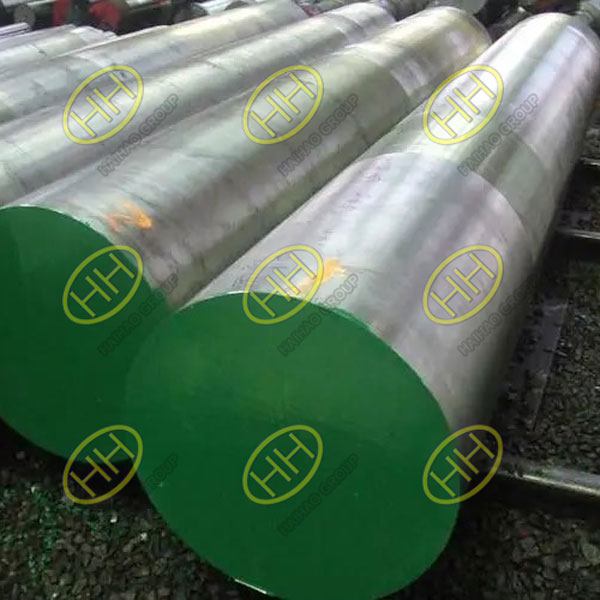

duplex 2205 stainless steel pipes

Corrosion Resistance of Duplex 2205

Duplex 2205 stainless steel offers an economically viable solution for many applications where the 300 series stainless steels are susceptible to chloride stress corrosion cracking. Stress corrosion cracking occurs when stainless steel is subjected to tensile stress in the presence of a solution containing chlorides. Higher temperatures also increase the susceptibility of stainless steel to stress corrosion cracking.

The combination of chromium, molybdenum, and nitrogen imparts excellent resistance to chloride pitting and crevice corrosion in duplex 2205. This resistance is crucial for services in marine environments, brackish water, bleaching operations, closed-loop water systems, and some food processing applications. In most environments, the high chromium, molybdenum, and nitrogen content of duplex 2205 provide better corrosion resistance than common stainless steels such as 316L and 317L.

Chemical Composition of Duplex 2205

| Cr | Ni | Mo | C | N | Mn | Si | P | S | Fe |

| 22.0-23.0 | 4.50-6.50 | 3.00-3.50 | ≤0.030 | 0.14-0.20 | ≤2.00 | ≤1.00 | ≤0.030 | ≤0.020 | Balance |

Key Features of Duplex 2205

- High resistance to chloride stress corrosion cracking

- Resistant to chloride pitting and crevice corrosion

- Good overall corrosion resistance

- Excellent resistance to chemical stress corrosion

- High strength

- Good weldability and machinability

Mechanical Properties of Duplex 2205

- Hardness (HB): ≤270 (quenched)

- Yield Strength 0.2% (N/mm2): ≥450 (quenched)

- Tensile Strength (N/mm2): 650-880 (quenched)

- Elongation (%): ≥25 (quenched)

Applications of Duplex 2205

- Chemical processing vessels, pipes, and heat exchangers

- Digesters, bleach washers, chip pre-steaming vessels in pulp and paper mills

- Food processing equipment

- Oilfield piping and heat exchangers

- Flue gas desulfurization equipment

Choose duplex 2205 stainless steel for its exceptional corrosion resistance, high strength, and versatility in various demanding applications. Its unique duplex structure ensures superior performance and reliability, making it a preferred choice for industries worldwide.As an expert in the field of pipeline systems, Haihao Group can provide customers with pipeline system products of different materials. If you need them, please feel free to contact us at any time.