Method and significance of chemical composition analysis of steel pipe

Ensuring the chemical composition of steel pipes is crucial for determining if a batch meets product standards. Here, we outline the methods used to test this composition and their significance.

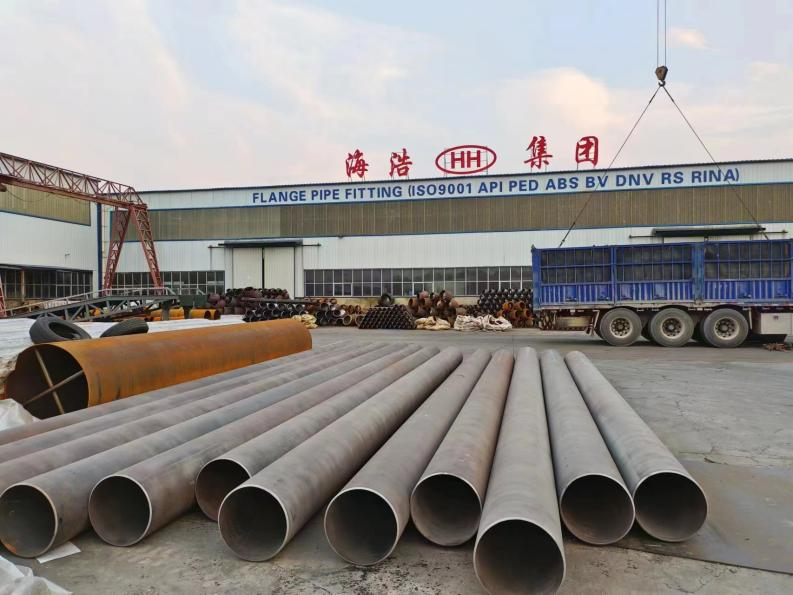

EN10225 pipe SAW 610×25.4×11.8m S355ML

Direct Reading Spectrometer

Utilizing the principles of spectroscopy, this method examines the emitted light from a substance when excited by external energy. It’s instrumental in identifying elements and their quantities in materials. Key features include:

High Sensitivity: Detects trace elements effectively.

Sensitive to Concentration Variations: Detects changes in element concentrations accurately.

Stable and Reproducible: Offers stable and consistent light sources.

Low Background Noise: Minimizes interference from external sources.

Non-destructive Analysis: Requires minimal sample damage.

Fast Analysis: Yields results in a short time, ideal for bulk and automated analysis.

Minimal Sample Requirement: Needs only a small sample for analysis.

Carbon-Sulfur Analyzer

HAIHAO GROUP

Basic Principle

This method involves combusting the sample in an oxygen-rich environment, converting carbon and sulfur into CO2, CO, and SO2 gases. These gases undergo catalytic conversion to CO2 and SO3, which are then measured to determine carbon and sulfur content, respectively. Key features include:

Wide Applicability: Suitable for various steel types and other inorganic materials.

Accurate and Deep Sampling: Provides more accurate results due to its depth sampling nature compared to surface analysis.

Analytical Range: Carbon: 0.6ppm – 6%, Sulfur: 0.6ppm – 0.4% (can be expanded by reducing sample weight).

Precision: Carbon: 0.3ppm or ≤ 0.5% RSD, Sulfur: 0.3ppm or ≤ 1.5% RSD.

Reading Resolution: Carbon/Sulfur 0.001ppm.

Calibration: Offers various calibration methods including linear, single-point, multipoint, and manual.

Analysis Time: ≤ 40 seconds.

Importance of Testing

Accurate chemical composition testing ensures compliance with steel grade standards. The data obtained aids in quality control, material selection, and process optimization. By employing reliable analytical methods like direct reading spectrometry and carbon-sulfur analysis, manufacturers uphold product integrity, meeting customer expectations and industry regulations. With cutting-edge technology and stringent quality control measures, companies like ours, Haihao Group, stand committed to delivering high-quality products for diverse pipeline applications.