Main risks and management measures at long-distance natural gas pipeline stations

In the operation of long-distance natural gas pipeline stations, there are some significant risks that require rigorous risk management strategies. As a leading expert in the field of pipeline systems, Haihao Group attaches great importance to pipeline system safety. Below we will share with you the main risks of long-distance natural gas pipeline stations and the countermeasures that can be taken.

1.Risk of pipeline natural gas leakage:

In the operation of long-distance natural gas pipeline stations, the most common risk is natural gas leakage. This risk often stems from issues with pipeline design and degradation of pipeline materials.

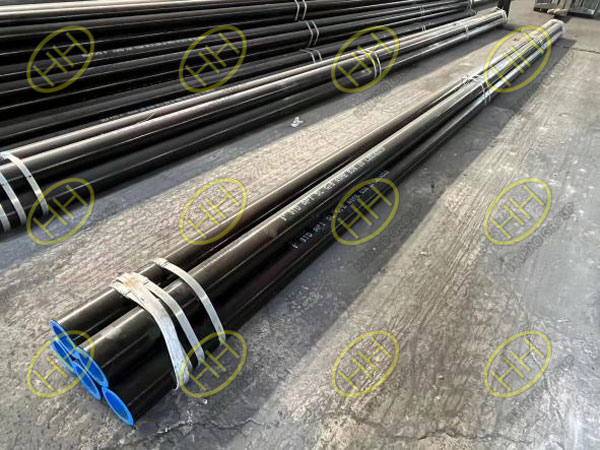

Black zinc rich epoxy paint coating steel pipe

Pipeline Design: Design challenges stem from the unique requirements of long-distance natural gas pipeline sites. The design of the pipeline must meet high requirements on gas flow, pressure resistance and influence on various environmental factors. Failure to address these requirements may pose a significant threat to the safety of the station.

Material properties: Due to the unique environment of long-distance natural gas pipeline stations, many pipelines are buried underground. These pipelines are in contact with soil for a long time underground and are susceptible to corrosion, resulting in continuous thinning of the pipe walls. Coupled with the internal and external pressure on the pipeline, it is more likely to cause natural gas leakage, resulting in safety accidents.

2.Risks caused by natural disasters:

The natural gas transported by long-distance natural gas pipelines is very long. During the transportation process over a long geographical span, there is a certain risk of natural disasters such as floods, earthquakes, and mudslides. Once these natural disasters occur, they will cause damage to long-distance natural gas pipelines, causing cracks or fractures in the pipelines, affecting the normal use of the pipelines.

3.Risks of equipment failure:

The diversity and complexity of equipment at long-distance natural gas pipeline stations make equipment failure a common risk. Equipment failure, control system failure, and pipeline leaks are the most common risks in this category.

Equipment failure: Long-term operation of equipment in a high-pressure environment can easily cause problems such as pipeline fatigue, equipment failure, and weak seals, which can lead to natural gas leakage failures.

Control system failure: In the system, once there is a problem in one link, it will inevitably have a major impact on the entire control system.

Pipeline leakage: Mainly caused by pipeline rupture caused by internal and external reasons, resulting in natural gas leakage. In serious cases, it may cause fire and other risks.

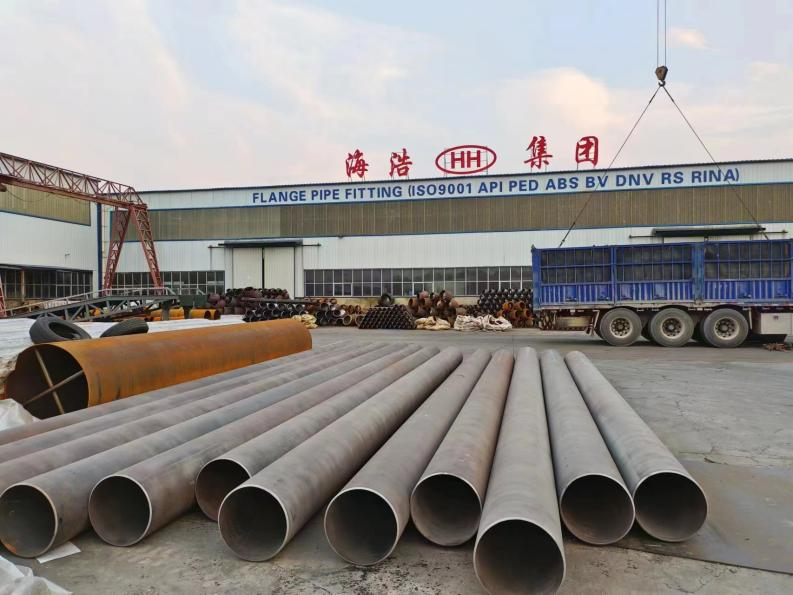

HAIHAO GROUP

4.Risks caused by overpressure at the station:

In order to make long-distance natural gas pipeline stations operate better, station equipment is often set to a relatively high pressure. This higher pressure setting is prone to overpressure problems due to improper pressure control, which in turn causes long-distance natural gas pipelines to operate. A safety accident occurred at the station due to overpressure.

In order to mitigate these risks, Haihao Group has adopted comprehensive risk management measures:

Risk management measures:

1.Strengthen training and education on station risk management:

Organize professional training programs to improve employees’ awareness and capabilities of station risk management. Customize the training content according to the actual needs of the station to ensure practical risk prevention.

2.Effective station equipment inspection and maintenance:

Carry out regular inspection and maintenance of station equipment, and timely discover and solve various faults that occur during operation. Use advanced information technology for real-time monitoring to improve the efficiency of equipment management.

3.Develop emergency management measures:

Based on the actual needs of the pipeline station, establish a complete emergency response organization and formulate emergency management procedures. Through 24-hour seamless monitoring, a strong theoretical basis for management is provided to ensure the safety of the station.

Haihao Group is committed to providing customers with safe and reliable pipeline system products and services. Our pipeline system products have been increasingly used in gas pipelines, oil pipelines, submarine pipelines and other scenarios. Haihao Group strives to establish industry safety standards and contribute to the safe operation of pipeline systems.