Key steps for steel pipe quality inspection to ensure excellent quality

Not long ago, an Italian customer ordered nearly 20 tons of steel pipes from Haihao. The materials include carbon steel and stainless steel. For this batch of steel pipes, the customer put forward requirements for quality control. The steel pipes needed to undergo chemical analysis, mechanical performance testing, and 100% hydraulic pressure testing. , 100% eddy current testing, below we will look at the specific conditions of these tests respectively.

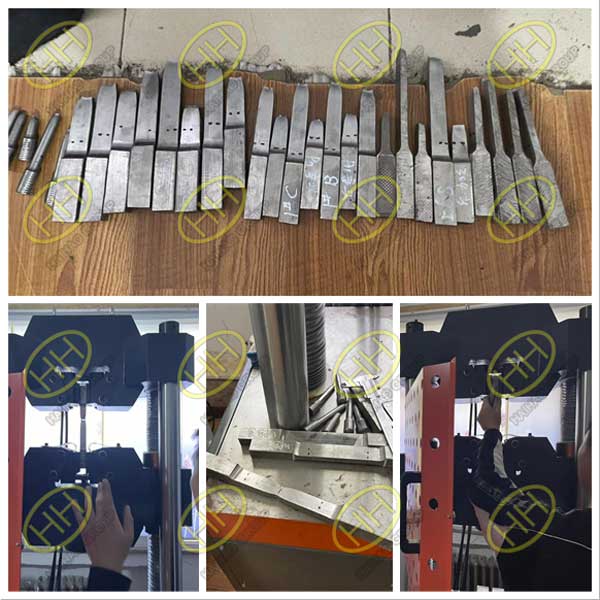

Tensile test

Chemical analysis and mechanical properties:

Chemical Analysis: Rigorous chemical analysis is performed to verify that the composition of the steel meets specified requirements. This analysis is critical to determining that the steel is suitable for the intended application.

Mechanical Properties: Mechanical testing evaluates the physical properties of steel, including strength, ductility, and hardness. These tests provide critical data on the performance of steel under various conditions.

Hydrostatic test

100% hydrostatic test:

Our pipes undergo 100% hydrostatic testing, a critical step in assessing their structural integrity. During this test, water is injected into the pipe and pressurized beyond its intended operating conditions. This ensures that the pipe can withstand the internal pressures that may be encountered in practical applications.

100% Eddy Current Testing (ECT):

Eddy current testing is used to detect surface and sub-surface defects, cracks or discontinuities in pipes. This nondestructive testing method efficiently identifies potential defects without compromising the structural integrity of the pipeline.

At every stage of the production process, our dedicated quality assurance team uses cutting-edge technology and rigorous testing protocols to ensure each steel pipe meets or exceeds industry standards. These meticulous testing methods not only comply with international regulations, they also demonstrate our strong commitment to delivering superior products to our customers.

By choosing our steel pipe products, our Italian customers can be confident in the quality and performance of the products they receive. We are committed to maintaining the highest standards of excellence and look forward to exceeding our customers’ expectations.