Identifying cracks crucial steps in ensuring product integrity

Distinguishing between quenching cracks, tempering cracks, forging cracks, and grinding cracks is pivotal for pinpointing the exact stage where the cracks occur, facilitating a thorough analysis of the underlying causes.

First and foremost, pay attention to the distinctive characteristics of quenching cracks and grinding cracks. Differentiating between cracks detected after quenching and those noticed after grinding is essential. When cracks are not visible during quenching but appear post-grinding, it’s imperative to discern whether they are quenching cracks or grinding cracks. This differentiation is relatively straightforward when cracks are free from contaminants. Focus on the morphology of the cracks, especially their development direction. Grinding cracks typically exhibit a perpendicular orientation to the grinding direction, appearing as parallel lines or resembling a tortoiseshell pattern. These cracks are shallow compared to quenching cracks, which tend to be deeper and larger, with no correlation to the grinding direction, often appearing as straight-line fractures.

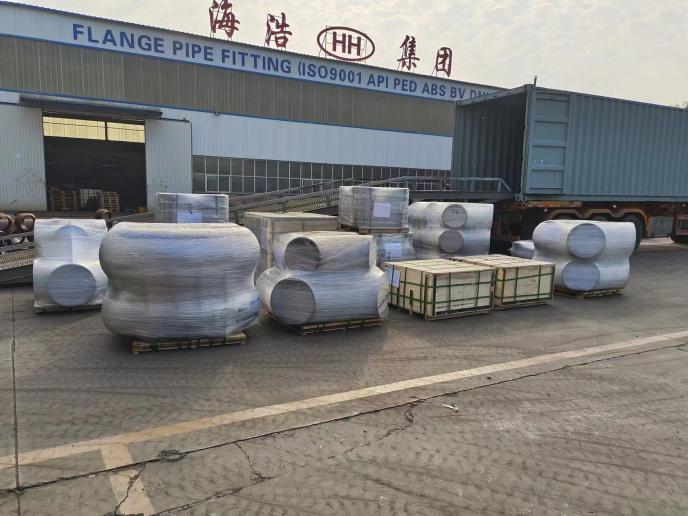

HAIHAO GROUP

Secondly, take note of the locations where cracks occur. Cracks that occur at sharp concave-convex corners, hole edges, engraved areas, stamped areas, and surface defects caused by mechanical processing are predominantly quenching cracks.

Thirdly, differentiate between quenching cracks and pre-quenching forging cracks or cracks caused by other factors by observing the fracture surfaces of components. If the crack surface appears white, off-white, or light red (due to quenching rust), it is likely a quenching crack. Conversely, if the crack surface exhibits a deep brown color, or even signs of oxidation, it indicates pre-quenching cracks formed during forging or rolling processes, which are subsequently enlarged during quenching. Quenching cracks generally form below the martensitic transformation point (MS point) and do not undergo oxidation.

Fourthly, quenching cracks typically exhibit intergranular fractures in the microstructure. If the fracture occurs within the grains rather than along the grain boundaries, it suggests fatigue cracking rather than quenching cracking.

Finally, the presence of decarburized layers around the cracks indicates pre-quenching cracks rather than quenching cracks. Quenching cracks result from the rapid cooling process during quenching and do not involve decarburization.

By meticulously following these steps and employing advanced inspection techniques, manufacturers can effectively identify and address cracks in stainless steel components, ensuring the integrity and reliability of the final products. At Haihao Group, we are committed to delivering stainless steel components that meet the highest standards of quality and performance.