Optimal cooling methods for representative steel grades

After steel rolling, various cooling methods can be employed to achieve desired material properties. These methods include cooling in air, low thermal conductivity materials, insulation boxes, unheated insulation pits, preheating insulation pits and furnaces, heated insulation pits and furnaces, and water cooling.

Heat treatment for stainless steel forgings

Below are the optimal cooling methods for representative steel grades:

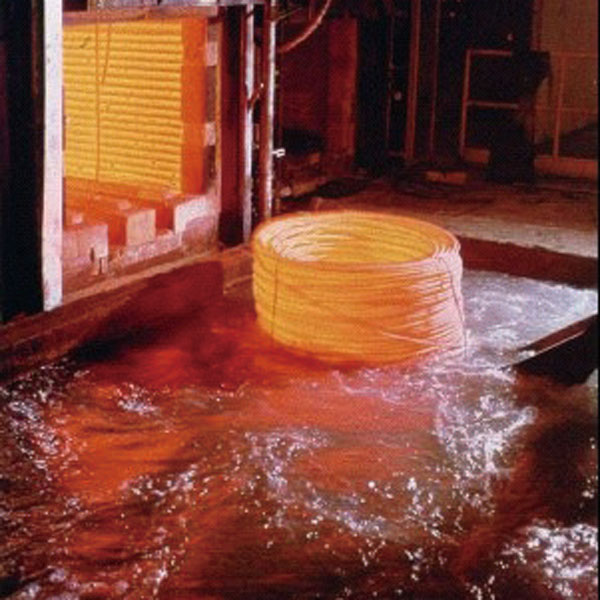

1.Bearing Steel and Spring Steel: For bearing and spring steels, it is crucial to complete the finishing rolling at low temperatures. Post-rolling, slow cooling is required to prevent the precipitation of network carbides. For bearing steel, a fast cooling followed by slow cooling process is adopted. The finishing rolling temperature for bearing steel is strictly controlled between 800-850°C to facilitate the breakdown of network carbides. If the finishing rolling temperature exceeds 900°C, water can be sprayed to rapidly cool the steel to 600-650°C to prevent further precipitation of network carbides, followed by slow cooling. To achieve this, a cooling water tank is placed in front of the finishing rolling mill to control the temperature of the incoming steel.

2.Quenched and Tempered Steel (Quenching + High-Temperature Tempering): Quenched and tempered steel has a martensitic structure. This steel type is known for its high strength, toughness, and ductility, making it suitable for high-strength components subject to impact or alternating loads, such as connecting rods and shafts. According to the continuous casting product outline, high-quality carbon structural steel and alloy structural steel account for 90% of the total production volume. Implementing precise temperature control for such large quantities of steel offers a competitive advantage.

heat treatment of pipeline product

3.High-Quality Carbon Structural Steel and Alloy Structural Steel: Both high-quality carbon structural steel and alloy structural steel belong to the sub-eutectoid steel category. The quenching temperature for sub-eutectoid steel is 30-50°C above AC3. For round steel with a diameter less than 40mm, a cooling water tank is installed in front of the finishing rolling mill to refine the grain size and achieve a martensitic structure after quenching. Subsequently, high-temperature tempering is performed to transform the quenched steel into a stable tempered structure by heating it below A1.