Exploring eddy current testing in pipeline systems

Eddy current testing, rooted in the principle of electromagnetic induction, plays a pivotal role in ensuring the integrity and reliability of pipeline systems. This non-destructive testing method relies on the generation of eddy currents within metallic materials when subjected to alternating magnetic fields. By analyzing the size and distribution of these eddy currents, defects in both ferromagnetic and non-ferromagnetic materials can be detected, enabling material sorting, measuring coating thickness, assessing component dimensions, and evaluating certain physical properties.

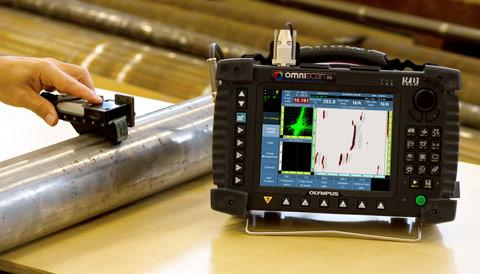

eddy current testing in pipeline systems

Key Equipment and Components

Eddy current testing systems typically comprise the following components: eddy current testing instruments, testing coils, and auxiliary devices such as magnetic saturation devices, mechanical drive mechanisms, recording devices, and demagnetization equipment. These components work in tandem, with an oscillator generating alternating current passed through the coil to produce an alternating magnetic field applied to the test piece.

Capabilities and Limitations

The capabilities of eddy current testing include:

Detection of defects on the surface and near-surface of metal materials, including welded joints and base materials.

Identification of defects on metal surfaces with non-metallic coatings.

Determination of defect locations and estimation of depths for surface-breaking or near-surface defects.

Sensitivity and detection depth are primarily determined by the excitation energy and frequency of the eddy currents.

However, eddy current testing does have limitations:

Difficulty in detecting buried defects within metal materials.

Challenges in detecting defects on the surface or near-surface of metal materials with coating thicknesses exceeding 3mm.

Limited capability in identifying fine cracks on weld surfaces.

Challenges in accurately determining the width and depth of defects.

Despite these limitations, eddy current testing remains an efficient and widely used method for quality assurance and defect detection in piping systems. Haihao Group is committed to operating and producing various pipeline system products. We ensure the safety and reliability of pipeline infrastructure in various industries by applying various advanced detection technologies. If you would like to know more about our products, please contact us.