Steel Casing Pipe also known as encasement pipe, is most commonly used in underground construction to protect utility lines of various types from getting damaged.Steel casing pipe is used in different types of horizontal underground boring, where the pipe is jacked into an augered hole in segments and then connected together by welding or by threaded and coupled ends, or other proprietary pipe connectors such as the interference-fit Permalok interlocking push-on joint.

| Size | Linear Mass lb/ft | Outside Diameter | Wall Thickness | Type of end-finish | |||||||||

| inch | mm | inch | mm | Grade | |||||||||

| H-40 | J-55 K-55 | M-65 | L-80 C-95 | N-80 1,Q | C-90 T-95 | P-110 | Q-125 | ||||||

| 4 1/2” | 9.5 | 4.5 | 114.3 | 0.205 | 5.21 | PS | PS | PS | – | – | – | – | – |

| 10.5 | 4.5 | 114.3 | 0.224 | 5.69 | — | PSB | PSB | – | – | – | – | – | |

| 11.6 | 4.5 | 114.3 | 0.25 | 6.35 | — | PSLB | PLB | PLB | PLB | PLB | PLB | – | |

| 13.5 | 4.5 | 114.3 | 0.29 | 7.37 | — | — | PLB | PLB | PLB | PLB | PLB | – | |

| 15.1 | 4.5 | 114.3 | 0.337 | 8.56 | — | — | – | – | – | – | PLB | PLB | |

| 5” | 11.5 | 5 | 127 | 0.22 | 5.59 | — | PS | PS | – | – | – | – | – |

| 13 | 5 | 127 | 0.253 | 6.43 | — | PSLB | PSLB | – | – | – | – | – | |

| 15 | 5 | 127 | 0.296 | 7.52 | — | PSLB | PLB | PLB | PLB | PLB | PLB | – | |

| 18 | 5 | 127 | 0.362 | 9.19 | — | — | PLB | PLB | PLB | PLB | PLB | PLB | |

| 21.4 | 5 | 127 | 0.437 | 11.1 | — | — | PLB | PLB | PLB | PLB | PLB | PLB | |

| 23.2 | 5 | 127 | 0.478 | 12.14 | — | — | – | PLB | PLB | PLB | PLB | PLB | |

| 24.1 | 5 | 127 | 0.5 | 12.7 | — | — | – | PLB | PLB | PLB | PLB | PLB | |

| 5 1/2” | 14 | 5.5 | 139.7 | 0.244 | 6.2 | PS | PS | PS | – | – | – | – | – |

| 15.5 | 5.5 | 139.7 | 0.275 | 6.98 | — | PSLB | PSLB | – | – | – | – | – | |

| 17 | 5.5 | 139.7 | 0.304 | 7.72 | — | PSLB | PLB | PLB | PLB | PLB | PLB | – | |

| 20 | 5.5 | 139.7 | 0.361 | 9.17 | — | — | PLB | PLB | PLB | PLB | PLB | – | |

| 23 | 5.5 | 139.7 | 0.415 | 10.54 | — | — | PLB | PLB | PLB | PLB | PLB | PLB | |

| 26.8 | 5.5 | 139.7 | 0.5 | 12.7 | — | — | – | – | – | P | – | – | |

| 29.7 | 5.5 | 139.7 | 0.562 | 14.27 | — | — | – | – | – | P | – | – | |

| 32.6 | 5.5 | 139.7 | 0.625 | 15.87 | — | — | – | – | – | P | – | – | |

| 35.3 | 5.5 | 139.7 | 0.687 | 17.45 | — | — | – | – | – | P | – | – | |

| 38 | 5.5 | 139.7 | 0.75 | 19.05 | — | — | – | – | – | P | – | – | |

| 40.5 | 5.5 | 139.7 | 0.812 | 20.62 | — | — | – | – | – | P | – | – | |

| 43.1 | 5.5 | 139.7 | 0.875 | 22.23 | — | — | – | – | – | P | – | – | |

| 6 5/8” | 20 | 6.625 | 168.28 | 0.288 | 7.32 | PS | PSLB | PSLB | – | – | – | – | – |

| 24 | 6.625 | 168.28 | 0.352 | 8.94 | — | PSLB | PLB | PLB | PLB | PLB | PLB | ||

| 28 | 6.625 | 168.28 | 0.417 | 10.59 | — | — | PLB | PLB | PLB | PLB | PLB | ||

| 32 | 6.625 | 168.28 | 0.475 | 12.06 | — | — | — | PLB | PLB | PLB | PLB | PLB | |

| 7 3/4” | 46.1 | 8.625 | 219.08 | 0.595 | 15.11 | — | – | – | P | P | P | P | P |

| 8 5/8” | 24 | 8.625 | 219.08 | 0.264 | 6.71 | — | PS | PS | – | – | – | – | – |

| 28 | 8.625 | 219.08 | 0.304 | 7.72 | PS | – | PS | – | – | – | – | – | |

| 32 | 8.625 | 219.08 | 0.352 | 8.94 | PS | PSLB | PSLB | – | – | – | – | – | |

| 36 | 8.625 | 219.08 | 0.4 | 10.16 | — | PSLB | PSLB | PLB | PLB | PLB | PSLB | – | |

| 8.625 | 219.08 | 0.45 | 11.43 | – | — | PLB | PLB | PLB | PLB | PLB | – | – | |

| 44 | 8.625 | 219.08 | 0.5 | 12.7 | — | – | – | PLB | PLB | PLB | PLB | – | |

| 49 | 9.625 | 244.28 | 0.557 | 14.15 | — | – | – | PLB | PLB | PLB | – | PLB | |

| 9 5/8” | 32.3 | 9.625 | 244.48 | 0.312 | 7.92 | PS | – | – | – | – | – | – | – |

| 36 | 9.625 | 244.48 | 0.352 | 8.94 | PS | PSLB | PSLB | – | – | – | – | – | |

| 40 | 9.625 | 244.48 | 0.395 | 10.03 | — | PSLB | PSLB | PLB | PLB | PLB | PLB | – | |

| 43.5 | 9.625 | 244.48 | 0.435 | 11.05 | — | – | PLB | PLB | PLB | PLB | PLB | – | |

| 47 | 9.625 | 244.48 | 0.472 | 11.99 | — | – | PLB | PLB | PLB | PLB | PLB | PLB | |

| 53.5 | 9.625 | 244.48 | 0.545 | 13.84 | — | – | – | PLB | PLB | PLB | PLB | PLB | |

| 58.4 | 9.625 | 244.48 | 0.595 | 15.11 | — | – | – | PLB | PLB | PLB | – | PLB | |

| 59.4 | 9.625 | 244.48 | 0.609 | 15.57 | — | – | – | – | – | P | – | – | |

| 64.9 | 9.625 | 244.48 | 0.672 | 17.07 | — | – | – | – | – | P | – | – | |

| 70.3 | 9.625 | 244.48 | 0.734 | 18.64 | — | – | – | – | – | P | – | – | |

| 75.6 | 9.625 | 244.48 | 0.797 | 20.24 | — | – | – | – | – | P | – | – | |

| 10 3/4” | 32.75 | 10.75 | 273.05 | 0.279 | 7.09 | PS | – | – | – | – | – | – | – |

| 40.5 | 10.75 | 273.05 | 0.35 | 8.89 | PS | PSB | PSB | – | – | – | – | – | |

| 45.5 | 10.75 | 273.05 | 0.4 | 10.16 | — | PSB | PSB | – | – | – | – | – | |

| 51 | 10.75 | 273.05 | 0.45 | 11.43 | — | PSB | PSB | PSB | PSB | PSB | PSB | – | |

| 55.5 | 10.75 | 273.05 | 0.468 | 12.57 | — | – | PSB | PSB | PSB | PSB | PSB | – | |

| 60.7 | 10.75 | 273.05 | 0.545 | 13.84 | — | – | – | – | – | PSB | PSB | PSB | |

| 65.7 | 10.75 | 273.05 | 0.595 | 15.11 | — | – | – | – | – | PSB | PSB | PSB | |

| 73.2 | 10.75 | 273.05 | 0.672 | 17.07 | — | – | – | – | – | P | – | – | |

| 79.2 | 10.75 | 273.05 | 0.734 | 18.64 | — | – | – | – | – | P | – | – | |

| 85.3 | 10.75 | 273.05 | 0.797 | 20.24 | — | – | – | – | – | P | – | – | |

| 11 3/4” | 42 | 11.75 | 298.45 | 0.333 | 8.46 | PS | – | – | – | – | – | – | – |

| 47 | 11.75 | 298.45 | 0.375 | 9.53 | — | PSB | PSB | – | – | – | – | – | |

| 54 | 11.75 | 298.45 | 0.435 | 11.05 | — | PSB | PSB | – | – | – | – | – | |

| 65 | 11.75 | 298.45 | 0.534 | 13.56 | — | – | – | P | P | P | P | P | |

| 71 | 11.75 | 298.45 | 0.582 | 14.78 | — | – | – | P | P | P | P | P | |

| 13 3/8” | 48 | 13.375 | 339.73 | 0.33 | 8.38 | PS | – | – | – | – | – | – | – |

| 54.5 | 13.375 | 339.73 | 0.38 | 9.65 | — | PSB | PSB | – | – | – | – | – | |

| 61 | 13.375 | 339.73 | 0.43 | 10.92 | — | PSB | PSB | – | – | – | – | – | |

| 68 | 13.375 | 339.73 | 0.48 | 12.19 | — | PSB | PSB | PSB | PSB | PSB | PSB | – | |

| 72 | 13.375 | 339.73 | 0.514 | 13.06 | — | – | – | PSB | PSB | PSB | PSB | PSB | |

| 18 5/8” | 87.5 | 18.625 | 473.08 | 0.435 | 11.05 | PS | PSB | PSB | – | – | – | – | – |

| 20” | 94 | 20 | 508 | 0.438 | 11.13 | PSL | PSLB | PSLB | – | – | – | – | – |

| 106.5 | 20 | 508 | 0.5 | 12.7 | — | PSLB | PSLB | – | – | – | – | – | |

| 133 | 20 | 508 | 0.635 | 16.13 | — | PSLB | – | – | – | – | – | – | |

| P–Plain end; S–Short round thread; L–Long round thread; B–Buttress thread | |||||||||||||

API 5CT Steel Pipe Oil Well Casing Pipe

Steel casing pipe protects one or many of various types of utilities such as water mains, gas pipes, electrical power cables, fiber optic cables, etc.

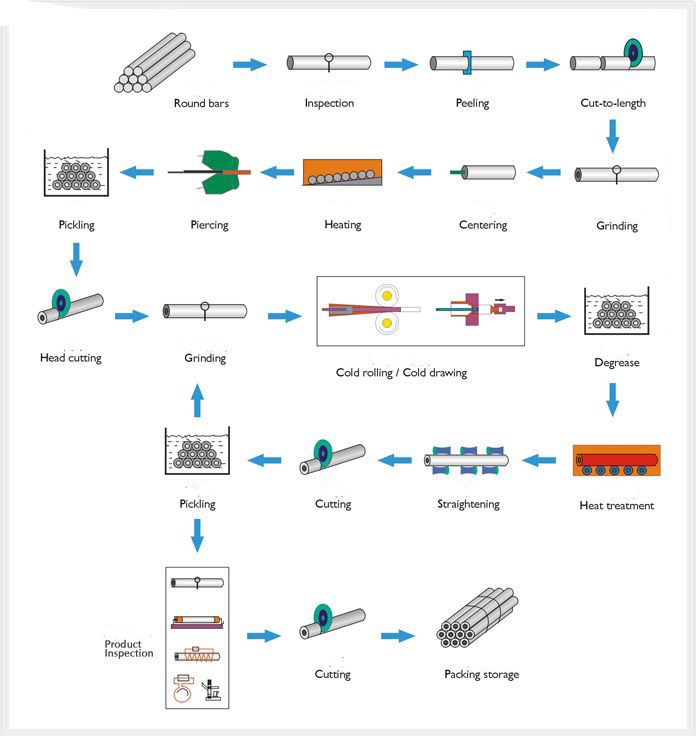

Product Process:

We have a large inventory of ASTM A25 2S teel Pipe Casing, Grade 2, Grade 3, and “limited service pipe”.Normal inventory includes pipe diameter sizes: 2″, 3″, 4″, 6″, 8″, 10″, 12″, 14″, 16″, 18″, 20″, 22″, 24″, 30″, and 36″. Also available in larger diameters to 110″ with wall thicknesses ranging in thickness from 0.25″ – 1″ depending upon the pipe OD.