What are ERW Steel Pipes?

Electric Resistance Welded (ERW) pipes are a popular choice for various piping solutions due to their efficient production process and reliable performance. Unlike seamless pipes that are extruded from solid billets, ERW pipes are produced by cold-forming steel sheets into cylindrical shapes and joining their edges through electrical resistance without using additional filler materials. This technique results in a strong, consistent weld that matches the pipe’s structure.

High-quality 3PE-coated A53 Gr.B ERW steel pipe producted at Haihao Group

Key Features of ERW Steel Pipes

Precision and Uniformity: ERW pipes exhibit high dimensional accuracy in terms of diameter and wall thickness, making them ideal for applications requiring tight tolerances.

Smooth Surface Finish: The manufacturing process ensures a refined surface, reducing the need for additional finishing treatments.

High Pressure and Structural Integrity: Suitable for medium to high-pressure applications, ERW pipes provide durability and resistance to deformation.

Cost-Effectiveness: Due to their streamlined production, ERW pipes are often more affordable compared to other welded pipe types.

Typical Applications of ERW Steel Pipes

ERW pipes are widely used in:

- Oil and gas transportation

- Water pipelines

- Structural engineering (scaffolding, fencing)

- Automotive industries

For instance, Haihao Group’s ERW pipes have been deployed in several Middle Eastern LNG projects and urban gas pipelines, complying with international standards.

Manufacturing Process Explained

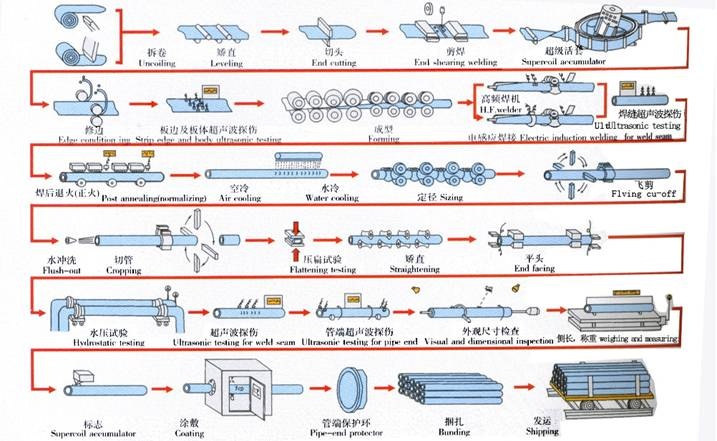

The manufacturing process of ERW Pipes

For Pipes Up to 4 Inches in Diameter

Forming: Flat steel strips (hot or cold rolled) are continuously fed into forming rolls that gradually shape the strip into a round tube.

Welding: Copper disk electrodes apply high-frequency electrical current to the tube edges, heating them until fusion occurs without additional welding material.

Finishing: The tube passes through sizing rolls to ensure diameter consistency and is then straightened, cut to length, and inspected.

Larger diameter ERW pipes follow a similar process but involve additional forming and calibration steps to maintain quality.

Specifications of Haihao Group’s ERW Steel Pipes

| Parameter | Specification |

|---|---|

| Standards | ASME B36.10, ASTM A53, API 5L |

| Sizes Available | 1/2″ – 24″ (DN15 – DN600) |

| Wall Thickness | SCH10 to SCH160 |

| Lengths | SRL (5-7m), DRL (10-14m), Customized (up to 18m) |

| Surface Finish | Black Painted, Galvanized, Bare Metal |

| End Finishes | Plain, Beveled, Threaded & Coupled |

For instance, Haihao Group’s ERW pipes have been deployed in several Middle Eastern LNG projects and urban gas pipelines, complying with international standards.

Why Choose Haihao Group for ERW Pipes?

- Quality Assurance: Each ERW pipe is manufactured according to recognized standards such as ASME B36.10 and API 5L, with certifications available upon request.

- Customizable Solutions: Whether your project requires specific coatings, lengths, or ends, Haihao offers tailored options to suit different engineering demands.

- Export Expertise: Our products have been successfully supplied to demanding markets including Europe, the Middle East, and Southeast Asia.

ERW steel pipes offer a cost-effective, high-performance solution for a range of applications, from fluid transmission to structural uses. At Haihao Group, our commitment to quality, customization, and customer satisfaction ensures that your piping systems meet both operational and regulatory requirements.

For more technical specifications or a custom quotation, please contact our sales team,Email:sales@haihaogroup.com

PREV: Hot Rolled Steel Pipe

NEXT: Galvanized Pipe