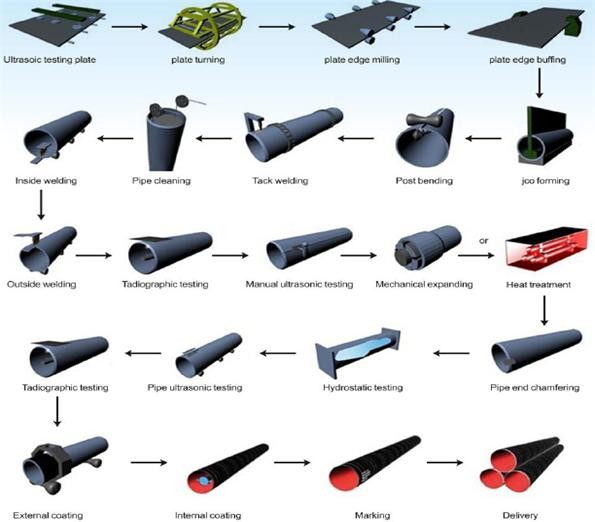

Longitudinal-seam Submerged Arc Welded (LSAW) pipes were made of steel plates cut from leveled hot rolled coils by both the JCOE and UOE (the forming process in which the plate like the letter “J”, “C”, “O” or “U” shape, then expansion) forming processes. Furthermore, the mechanical properties of the pipe base metal and weld metal were tested, and the results were in accordance with the corresponding pipe specification API SPEC 5L or DNV-OS-F101, which showed that domestic LSAW pipes could be used for oil and gas pipelines.

| Longitudinal Seam Submerged Arc Welded (LSAW) Steel Pipes | |

| Standard | API 5L PSL1/2, EN-10208-1/2, GB9711.1/2, ISO, API 5CT, ASTM A53 |

| Steel Grade | B, X42 up to X70; L245, L290 up to L485 |

| Usage | Used for the conveyance of water, gas, or petroleum products |

| Size | LSAW from 219.1mm to 2000mm, thickness from 5mm to 25.4mm |

| Ends | Beveled ends with protector |

| Surface | Bare / Varnish coating / FBE,3PE coating DIN30670 / or by client option |

| Packing | Casing, bundled shipping in containers or by break bulk vessel |

Longitudinal-seam Submerged Arc Welded (LSAW) pipes with JCOE Process