The role of Beryllium (Be) in steel microstructure and heat treatment

1.Microstructural Impact and Heat Treatment

Beryllium (Be) is a rare lightweight metal with a strong affinity for oxygen and sulfur, making it an effective deoxidizer and desulfurizer in steelmaking. Be narrows the austenite phase region in steel and, when in solid solution, increases the hardenability of the steel. Additionally, Be can form intermetallic compounds with iron (Fe) and special carbides with carbon. When the composition is carefully balanced and properly treated, these compounds can result in significant precipitation strengthening of the steel.

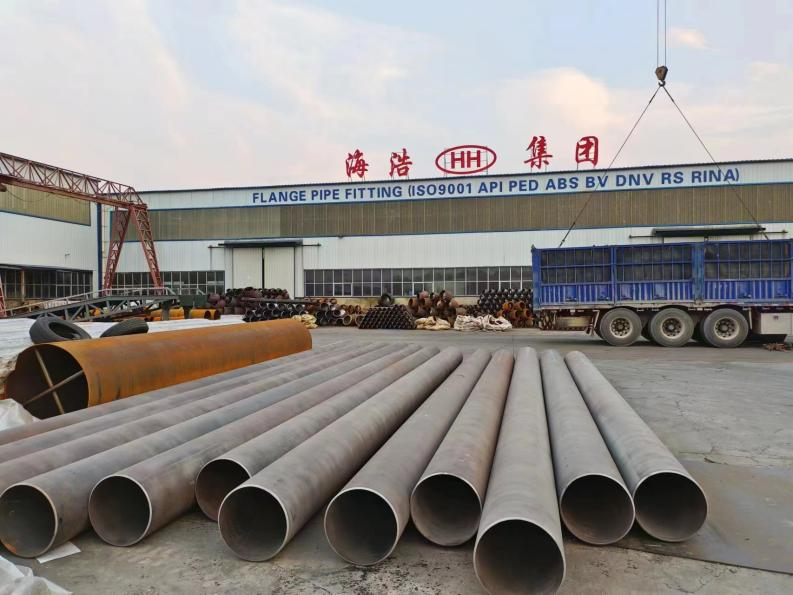

HAIHAO GROUP

2.Effects on Mechanical Properties

Beryllium has a strong solid solution strengthening effect on ferrite, which enhances the steel’s high-temperature strength and creep resistance. This makes steel with Be more suitable for applications that require enhanced mechanical performance under high-temperature conditions.

3.Influence on Physical, Chemical, and Processing Properties

In certain alloys, such as Invar and constant elasticity alloys, adding 0.5% to 1.0% Be and adjusting other elements can improve the overall performance. However, it’s important to note that some Be compounds are harmful to human health, so adequate protective measures must be taken during steel production to ensure safety.

Applications of Beryllium in Steel

1.Usage in Steel

Due to its rarity and high cost, Be is not commonly used in standard alloy steels. Instead, it is primarily reserved for special-purpose steels and alloys used in the atomic energy industry and military applications, where its unique properties can be fully leveraged.

2.Special Applications

Beryllium’s unique characteristics make it indispensable in specific high-performance applications, particularly those requiring exceptional high-temperature strength, creep resistance, and solid solution strengthening. As such, Be is a critical element in the development of steels and alloys for advanced technological and industrial uses.

While beryllium’s use in steel is limited due to its cost and potential health risks, its ability to significantly enhance steel’s mechanical properties and performance in specialized applications makes it a valuable element in certain industries.