Introduction to the types of quenching media for heat treatment of pipe fittings

In the realm of heat treatment, the quenching process plays a pivotal role in defining the properties of a workpiece. The medium used for quenching, referred to as quenching media, significantly influences the transformation of the material’s structure. An ideal quenching medium should facilitate the transformation of the workpiece into martensite while minimizing the occurrence of excessive quenching stress. Achieving this delicate balance involves controlling the cooling rate at different temperature ranges, as outlined by the C-curve.

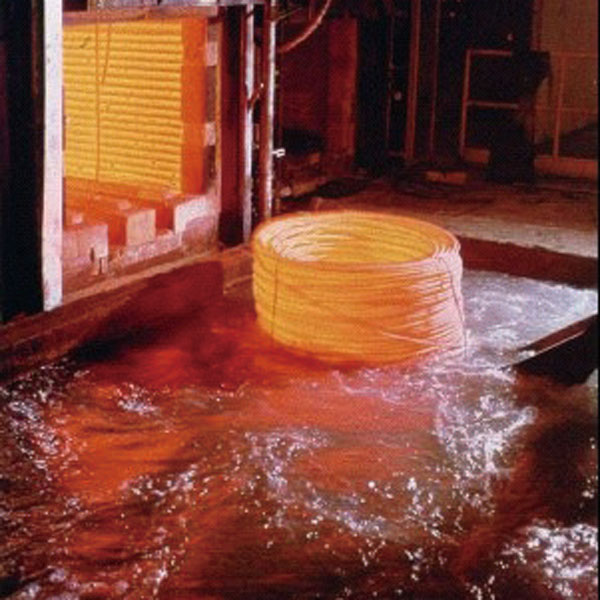

heat treatment of pipeline product

Common Types of Quenching Media:

Water:

Advantages: Water is widely accessible, cost-effective, and exhibits stable properties. It is a high-cooling-capacity quenching medium.

Drawbacks: In the “nose” region of the C-curve (around 500-600°C), water, in its vapor phase, cools relatively slowly, creating a “soft spot.” Additionally, in the martensite transformation temperature range (300-100°C), rapid cooling can induce significant internal stresses, potentially causing deformation or cracking.

Saltwater and Alkali Water:

Method: Adding salt or alkali to water increases its cooling capacity in the high-temperature range.

Considerations: While enhancing cooling, these solutions have high corrosiveness. Typically used for quenching carbon steel and low-alloy structural steel components.

Oil:

Type: Mineral oils such as engine oil, transformer oil, and diesel are common quenching mediums.

Variants: Newer types include high-speed quenching oil, bright quenching oil for maintaining a polished surface, and vacuum quenching oil for vacuum heat treatment processes.

Polyethylene Glycol Solutions and Nitrate Solutions:

Polyethylene Glycol Solution: Offers cooling capabilities between water and oil. Forms a gel film during quenching, influencing the cooling rate.

Nitrate Solution: Comprising sodium nitrate, sodium nitrite, and potassium nitrate, this solution’s cooling capacity varies with temperature, making it a versatile alternative for dual-medium quenching.

Heat treatment for stainless steel forgings

In addition to these traditional quenching media, newer solutions like polyethylene glycol and nitrate solutions are gaining attention for their unique cooling characteristics.

Understanding the intricacies of different quenching media allows us at Haihao Group to tailor our heat treatment processes, ensuring optimal performance and properties for our pipe components. Our commitment to mastering these techniques reflects our dedication to delivering high-quality products that meet the specific requirements of each project.

For inquiries or orders, feel free to reach out to Haihao Group. Your satisfaction is our primary goal!