Ensuring mechanical strength: Rigorous testing of pipe fittings at Haihao Group

At Haihao Group, we understand that the mechanical strength of pipe fittings is paramount to the integrity of pipelines in various industries. To guarantee the highest quality and reliability, we subject all our pipe fittings to stringent mechanical strength testing.

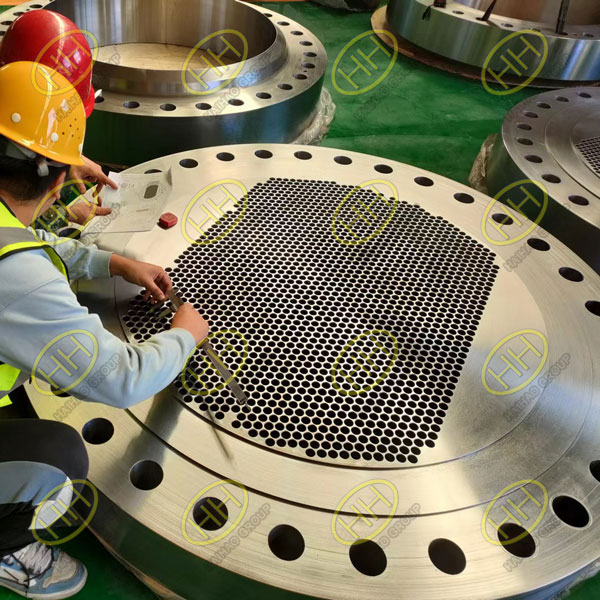

tube sheet flange inspection

Why Mechanical Strength Testing Matters:

Mechanical strength testing is crucial because it helps us determine how well a pipe fitting can withstand different mechanical forces and loads, ensuring that it performs safely and reliably in real-world applications. The tests we conduct assess various aspects of a pipe fitting’s strength and durability, including:

- Tensile Strength: This test measures the pipe fitting’s ability to resist axial forces, simulating the stresses it may encounter during installation and operation.

- Impact Resistance: Impact tests assess the fitting’s ability to absorb energy when subjected to sudden impact or shock loads, mimicking conditions that may arise in the field.

- Hardness: Hardness tests determine the material’s resistance to indentation or abrasion, providing insights into its wear resistance and longevity.

- Compression Strength: Compression tests assess how well the fitting can withstand axial loads pushing inward, which is vital for components under compressive stress.

- Bend Strength: Bend tests evaluate the fitting’s resilience to bending or flexing, which is essential for components subjected to bending forces.

- Shear Strength: Shear tests measure the fitting’s resistance to forces acting parallel to its surface, simulating conditions such as cutting or shearing.

Custom Elbows

Our Rigorous Testing Process:

At Haihao Group, we follow a comprehensive quality assurance process that involves rigorous mechanical strength testing. Our testing process is based on international standards and industry best practices. It includes:

- Selection of Test Samples: We carefully select representative samples of our pipe fittings for testing.

- State-of-the-Art Testing Equipment: We utilize advanced testing equipment and technology to ensure accurate and reliable results.

- Compliance with International Standards: Our tests adhere to recognized international standards to guarantee consistency and comparability.

- Certified Technicians: Our testing is conducted by certified technicians with expertise in mechanical testing.

- Documentation: Detailed records are kept throughout the testing process to maintain transparency and traceability.

Why Choose Haihao Group:

Our commitment to ensuring the mechanical strength of our pipe fittings is unwavering. We understand the critical role our products play in various industries, and we’re dedicated to contributing to the success and safety of your projects.

When you choose Haihao Group, you’re choosing quality, reliability, and peace of mind. Our pipe fittings are built to withstand the toughest conditions, and our rigorous testing procedures are a testament to our dedication to excellence.

If you require pipe fittings that meet and exceed industry standards for mechanical strength, look no further than Haihao Group. Contact us today to discuss your requirements and experience firsthand the exceptional quality and reliability of our products. Your success and safety are our top priorities.