Difference between seamless elbow and welded elbow

Seamless elbow is manufactured by the seamless steel pipe, through hot push, press or extrusion processes, and there is no seam on the elbow body.Welded elbow small than DN600 is manufactured by welded steel pipe, is made in the same process as seamless elbow.But there is a welded seam on the elbow body.Welding elbows larger than DN600 are made of steel plates, and there will be 2 welds. If you need the seamless elbows when the size is above DN600, please inform in advance, we can also produce them.There are the difference between seamless elbow and welded elbow.

JIS B2312 SS304 45 Degree Elbows

Different raw materials: seamless elbow is pushed by seamless pipe. Welded elbow refers to butt welding elbow and straight seam elbow.

Different appearance: butt welding elbow has two welds and straight seam elbow has one weld. Seamless elbows have no welds.

Elbows by two halves

Different performance characteristics: Compared with welded elbow, seamless elbow has the following advantages: health and non-toxic, light weight, good heat resistance, good corrosion resistance, good thermal insulation, good impact resistance and long service life.

Different prices: because the manufacturing process of seamless elbow is complex, the cost is more expensive than that of welded elbow. The welded elbow is mainly made of steel plate (steel strip) by secondary welding. Therefore, it is cheap and widely used.

Different uses: seamless elbows are mainly used as pipes or structural parts for conveying fluid, and are mainly used in the machinery industry. The welded elbow is mainly used in the construction industry, such as water supply, gas, compressed air and other low-pressure fluids. It is worth noting that seamless pipes are used for pressure pipes.

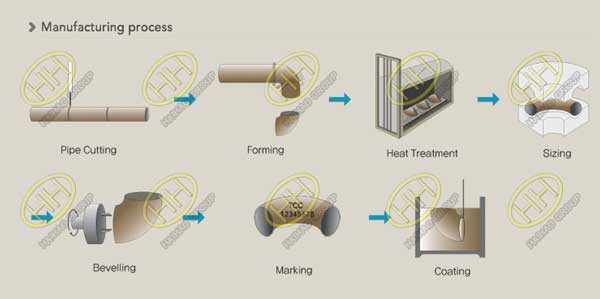

Seamless elbow production process

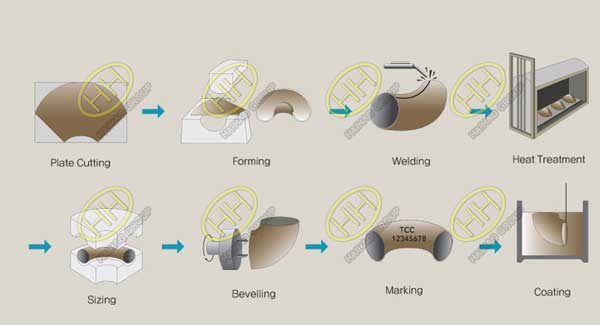

Welded elbow production process

Haihao Group manufacture elbow products for about 40 years,the products sells well all over the world for the high quality.If you have any question,please contact us! Email:sales@haihaogroup.com