Advantages and Disadvantages of Socket Weld Pipe Fittings

The socket weld is a pipe attachment detail in which a pipe is inserted into a recessed area of a Valve, fitting or flange.They joint construction is a good choice wherever the benefits of high leakage integrity and great structural strength are important design considerations.

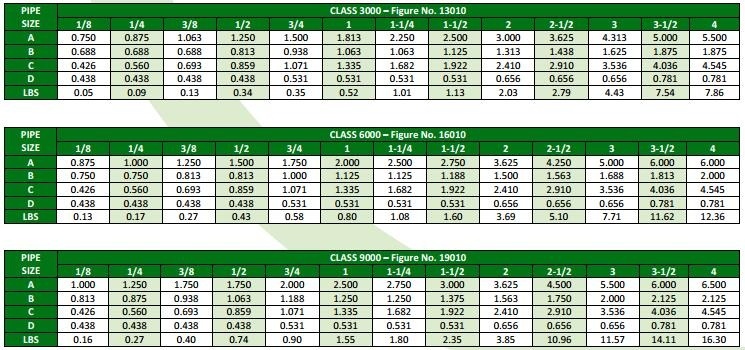

Dimension-of-socket-weld-pipe-fittings.

Dimension-of-socket-weld-pipe-fittings.

Advantages of Socket Weld Pipe Fittings

1.The socket weld pipe fittings can be used in place of threaded fittings, so the risk of leakage is much smaller.

2.Socket weld pipe need not be beveled for weld preparation.

3.The weld metal can not penetrate into the bore of the pipe.

4.Construction costs are lower than with butt-welded joints due to the lack of exacting fit-up requirements and elimination of special machining for butt weld end preparation.

Disadvantages of Socket Weld Pipe Fittings

1.Socket weld pipe fittings are unacceptable for UHP pressure in Food Industry application since they do not permit full penetration and leave overlaps and crevices that are very difficult to clean, creating virtual leaks.

2.The socket weld pipe fittings should ensure for a expansion gap of 1/16 inch (1.6 mm) between pipe and the shoulder of the socket.

3.The expansion gap and internal crevices left in socket welded systems promotes corrosion and make them less suitable for corrosive or radioactive applications where solids buildup at the joints may cause operating or maintenance problems. Generally require butt welds in all pipe sizes with complete weld penetration to the inside of the piping.

Dimension-of-socket-weld-pipe-fittings.

Dimension-of-socket-weld-pipe-fittings.

Hebei Haihao as a first socket weld pipe fittings manufacturer of elbow,flange,coupling,tee etc.We have more than 30 years of experience to produce.Welcome to contact us when you have any need about all kinds of socket weld pipe fittings.