The quality inspection of seamless steel pipes

At Haihao Group, we take immense pride in producing high-quality seamless steel pipes that meet the stringent demands of various industries. As a testament to our commitment to excellence, we have implemented a rigorous quality inspection process to guarantee the superior performance and reliability of our products. Join us as we delve into the meticulous steps we undertake to ensure the impeccable quality of our seamless steel pipes.

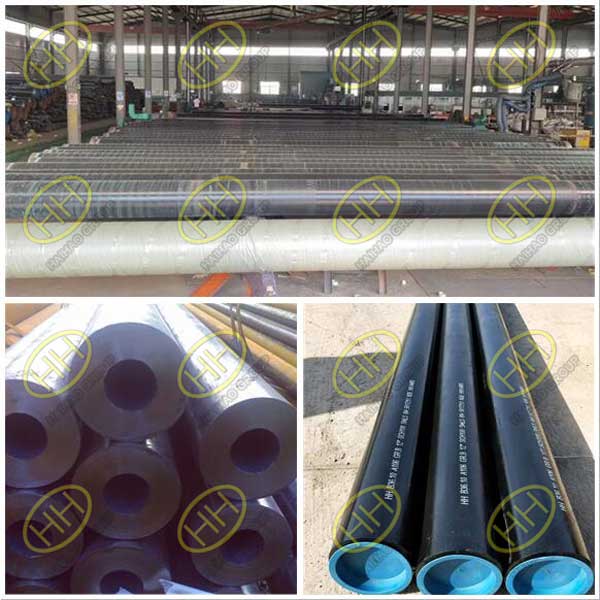

API 5L PSL1 Grade B seamless steel pipes

Raw Material Selection:

We begin our quality journey by carefully selecting the finest raw materials. Only premium-grade steel, sourced from reputable suppliers, makes its way into our manufacturing process. By adhering to strict material specifications and conducting comprehensive material testing, we ensure that our seamless steel pipes possess exceptional strength, durability, and resistance to corrosion.

Precision Manufacturing:

Our state-of-the-art manufacturing facilities house advanced equipment and cutting-edge technologies, allowing us to produce seamless steel pipes with utmost precision. Throughout the production process, our skilled technicians and engineers closely monitor every stage to guarantee dimensional accuracy, smooth surface finishes, and uniform wall thickness. This meticulous approach ensures that our pipes meet and exceed industry standards.

Non-Destructive Testing (NDT):

To assess the integrity and reliability of our seamless steel pipes, we employ a range of non-destructive testing techniques. These include ultrasonic testing (UT), magnetic particle inspection (MPI), radiographic testing (RT), and liquid penetrant testing (PT). These methods detect any potential defects or discontinuities, ensuring that our pipes are free from imperfections that could compromise their performance under demanding conditions.

Seamless steel pipes

Mechanical and Chemical Analysis:

Comprehensive mechanical and chemical analyses are conducted on our seamless steel pipes to validate their mechanical properties and chemical composition. Through tests such as tensile strength, yield strength, elongation, and impact resistance, we ensure that our pipes exhibit the desired mechanical characteristics. Chemical analysis guarantees the compliance of our pipes with specific alloy composition requirements.

Dimensional and Visual Inspection:

Our quality inspection process includes rigorous dimensional and visual examinations. Our dedicated team meticulously checks the dimensions, tolerances, and surface conditions of each seamless steel pipe. This meticulous scrutiny ensures that our pipes align with precise specifications and exhibit flawless visual appearances, free from any visible defects or imperfections.

Documentation and Traceability:

We place great importance on documentation and traceability throughout our quality inspection process. Each seamless steel pipe undergoes thorough documentation, including test reports, certificates of compliance, and material traceability records. This meticulous documentation ensures transparency and provides our customers with confidence in the quality and origin of our products.

At Haihao Group, our unwavering commitment to quality inspection is the cornerstone of our success. We continuously invest in research, technology, and training to enhance our inspection capabilities and stay at the forefront of the industry. As a result, our seamless steel pipes have earned the trust and recognition of clients across diverse sectors, including oil and gas, petrochemicals, power generation, and more.

Partner with Haihao Group for seamless steel pipes that exemplify unrivaled quality, reliability, and performance. Contact us today to discuss your specific requirements and experience the assurance of seamless excellence in pipe manufacturing.