An overview of EN 10204 3.1 and 3.2 certificates

EN 10204 is a European standard that defines the types of inspection documents supplied to the purchaser for the delivery of all metallic products, such as plates, sheets, bars, forgings, and castings, regardless of the manufacturing method. This standard ensures that different types of inspection documents are provided as required by the order, ensuring compliance with specific requirements.

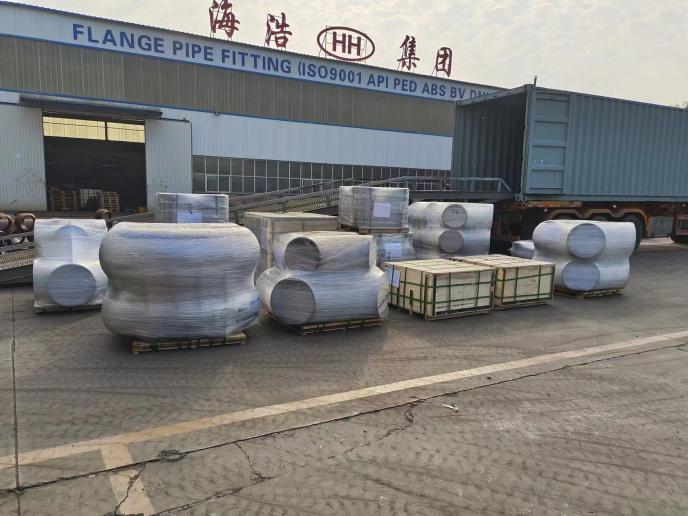

HAIHAO GROUP

EN 10204 Type 3.1 Inspection Certificate

The Type 3.1 inspection certificate is a document issued by the manufacturer. In this document, the manufacturer declares that the supplied products meet the requirements of the order and provides the results of specific tests. The tests and specimens to be tested are defined by the product specification, official regulations, corresponding rules, and/or the order. This document must be validated by an inspection representative authorized by the manufacturer, who is independent of the manufacturing department.

It is permissible for the manufacturer to transfer the results of specific inspections performed on the initial or raw materials and purchased products to the Type 3.1 inspection certificate, provided that the manufacturer employs traceability procedures and can supply the required inspection documents.

Stainless steel pipe fittings

EN 10204 Type 3.2 Inspection Certificate

The Type 3.2 inspection certificate is more rigorous and involves dual validation. It is prepared by an inspection representative designated by the manufacturer, who is independent of the manufacturing department, and an inspection representative appointed by the purchaser or an official regulatory body. This certificate declares that the supplied products comply with the requirements of the order and includes the results of specific tests.

Similar to the Type 3.1 certificate, the manufacturer is allowed to transfer the results of specific inspections performed on the initial or raw materials and purchased products to the Type 3.2 inspection certificate, as long as traceability procedures are followed and the required inspection documents can be provided.

Key Differences and Applications

Type 3.1 Certificate: This certificate is issued by the manufacturer’s internal quality department and is suitable for most industrial applications, providing adequate assurance of product quality.

Type 3.2 Certificate: This certificate, requiring dual validation from both the manufacturer and an independent third party or purchaser’s representative, offers a higher level of assurance and is used for critical applications where the highest level of quality verification is necessary.

Both certificates play a crucial role in the international trade of metallic products, ensuring that both suppliers and purchasers have a clear and reliable understanding of the product’s quality and compliance with specified standards. These certificates are extensively used in industries such as steel, petrochemical, shipbuilding, and more, providing a robust framework for quality assurance and traceability in the supply chain.