Socket Weld Flange

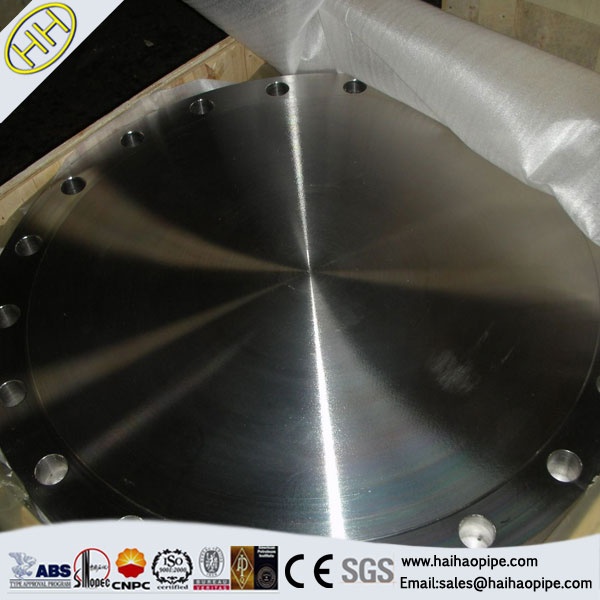

Blind Flanges are manufactured without a bore and used to blank off the ends of piping, Valves and pressure vessel openings.

From the standpoint of internal pressure and bolt loading, blind flanges, particularly in the larger sizes, are the most highly stressed flange types.

This flange permits easy access to a line once it has been sealed.It sometimes can be machined to accept a nominal sizes pipe to which a threaded or welded reduction is being made.

Haihao steel blind flanges are available in various sizes and material for you to choose from.

| Size | 1/4″-160″DN8-DN4000 |

| Pressure | America Series:

Class 150 ,Class 300, Class 600, Class 900A ,Class 1500,Class 2500. Europe Series: PN2.5,PN6,PN10,PN16,PN25,PN40,PN63,PN100,PN160,PN250,PN320,PN400. |

| Type | America Series:

Flat face(FF),Raised face(RF),Tongue(T),Groove(G),Female(F),Male(M),Ring type joints face(RJ/RTJ) Europe Series: Type A(Flat Face),Type B(Raised Face),Type C(Tongue),Type D(Groove),Type E(Spigot),Type F(Recess),Type G(O-Ring Spigot),Type H(O-Ring Groove) |

| Material | Carbon steel:

ASTM A105,ASTM A105N,GB 20,C22.8. Alloy steel: ASTM/ASME A234 WP 1-WP 12-WP 11-WP 22-WP 5-WP 91-WP 911 Stainless steel: ASTM/ASME A403 WP 304-304L-304H-304LN-304N ASTM/ASME A403 WP 316-316L-316H-316LN-316N-316Ti ASTM/ASME A403 WP 321-321H ASTM/ASME A403 WP 347-347H Low temperature steel: ASTM/ASME A402 WPL 3-WPL 6 High performance steel: ASTM/ASME A860 WPHY 42-46-52-60-65-70 |

| Standards | ASME ANSI B16.5,ASME ANSI B16.47.API 605,API 6L.

MSS SP 44 CSA Z245.12 EN1092-1,EN1759-1. DIN2566. BS1560,BS 4504,BS 10. AFNOR NF E29-200-1 ISO7005-1 AS2129 JIS B2220 UNI 2276. UNI 2277.UNI 2278 .UNI 6089 .UNI 6090 |

| Industrial Processes | Die forging,Machining. |

| Application | Natural gas,chemical,petroleum,ship building,marine,paper making,metallurgy,electric, power,boiler etc. |

Hebei Haihao group as a first class manufacturer of blind flange(BL flange) in China,supplys a variety of steel flanges to satisfy our customers’ specifica requirements,which include different size,different schedule,different pressure and different finish faces. Our products are produced strictly according to the required standard. Our raw material for weld neck flanges all are purchased from big steel companies which can make sure the material in a high quality.